10

Start-Up Procedures

CAUTION: Break-in period

Before initial use, open the drain valve and run the

compressor without air tools attached and through open

air line for 30 minutes to break-in pump parts.

1.

Verify that the pressure switch is in the OFF position.

(Figure 5)

Figure 5

2. Turn regulator counter clockwise to close.

3. Verify that the pressure gauge reads zero.

4. Open the drain valve so that air flow is permitted.

5. Turn the pressure switch to the ON position.

6. Adjust regulator to desired pressure.

7. Allow pressure in receiver tank to build.

Note: This electric model is equipped with a pressure

switch that automatically turns the motor off when the

tank pressure reaches its preset level. Once air

pressure in the tank drops to a preset low level, the

pressure switch automatically turns the motor back on.

WARNING: Overheating

This compressor is equipped with “auto shut off”.

However, failure to allow adequate cooling ventilation or

a restriction in the intake airflow may cause the

machine to overheat.

WARNING: Inflatables/Low PSI tire

Never use compressor to inflate small low-pressure

objects, i.e., balloons/inflatables, small or low volume

PSI tires. It is easy to over-pressurize them, causing

them to rupture. Identify the inflation capacity of an

object prior to filling it with air. Use a gauge to check the

pressure regularly when inflating anything.

Proper Air Hose and Tool Use

Pressure Control Related Devices

Never remove, adjust, bypass, change, modify or make

substitutions for safety/relief valves, pressure switches

or other pressure control related devices. Pressurizing

beyond the limits of the compressor could result in an

explosion.

WARNING: Overpressurization hazard

NEVER over-pressurize the receiver tank or air tools

beyond nameplate capacity. Exceeding the pressure

rating could cause them to explode or fly apart.

Compressor - Tool Requirements

Compressor and attachments must be sized properly

for pressure and air volume.

Consider the maximum pressure requirements and

air volume requirements of each. (The volume rating

of your compressor is listed in the “

Specifications

”

section.)

CAUTION: Tool overpressure hazard

Do not operate this unit with any tool rated less than the

maximum operating pressure of the unit (135 PSI)

unless a properly sized regulator limiting pressure is

used before the tool.

Attaching/Disconnecting Air Hose and Tools

CAUTION: High pressure stream hazard

High-pressure air stream can pierce skin and underlying

tissues, leading to serious injury and possible

amputation. Such an injection injury can result in blood

poisoning and/or severe tissue damage. High-pressure

air stream can also cause flying debris and possible

surface damage.

On a fixed line distribution system the flexible hosing

and tools would typically be connected at a terminating

point. In some cases where a fixed system does not

exist, the flexible hosing can be attached to the quick

connect fitting on the main compressor outlet or after the

user installed regulator.

CAUTION: Air tools hazard

Do not attach air tools to open end of the hose until

start-up is completed and the unit checks out OK.

Quick Connect Procedure:

Keep finger off tool or activation switch until ready

to use.

Pull quick connect collar back (Figure 6a).

Push hose or attachment firmly against stop.

Let go of collar (Figure 6b).

Pull and rotate slightly (hose or attachment) to

assure a tight connection.

WARNING: Projectile hazard

Air tool or attachment can become a projectile and

cause serious personal injury or damage if not securely

attached to the air hose.

On

Off

Summary of Contents for 25653

Page 3: ...3 Appendix A Lubricants and Compatibility 22 Alternate Lubricants 22 Limited Warranty 23 ...

Page 16: ...16 Parts Explosions Model 25653 Rev A Pump not shown on this parts explosion ...

Page 18: ...18 Parts Explosions Model 25654 Rev A Pump not shown on this parts explosion ...

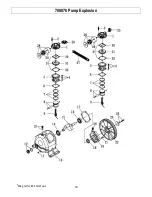

Page 20: ...20 788876 Pump Explosion Wing nut for 28 not shown ...

Page 24: ...24 Assembled by Northern Tool Equipment Company Inc Burnsville MN 55306 NorthernTool com ...