12

Maintenance & Repair

WARNING: Maintenance hazards

ALWAYS disconnect, lock out and tag the main power supply and then release air pressure from the receiver tank before

cleaning, adjusting, or servicing the compressor. Make sure all guards and shields are replaced before re-starting.

Maintenance Schedule Summary

Item

Frequency

Inspect safety/relief valves

Weekly

Check pump oil level

Weekly

Inspect air filter

Weekly

Replace every 12 months or 1000 hours of

use

Inspect for air leaks

Monthly

Change pump oil

After first 50

hours of use

Every 3 months or 500 hours of use

Inspect & drain receiver tank

Daily

Check drive belt tension and alignment

Monthly

Dust/debris removal

Monthly

See detailed instructions for each maintenance item below.

Detailed Instructions – Maintenance & Repair

NOTICE

Dispose of used pump oil in a manner that is

compatible with the environment and in accordance

with local, state, and federal laws and regulations.

Take used oil in a sealed container to your local

recycling center or service station for reclamation.

Do not throw it in the trash, pour it on the ground, or

pour it down a drain.

No Modifications.

Never modify or alter the

compressor in any way. Modifications can create

serious safety hazards and will void the warranty.

Inspect Safety/Relief Valve

This valve should be inspected and tested on a weekly

basis.

The safety valve automatically releases air if the

tank pressure exceeds the preset maximum.

Check the safety/relief valve by pulling the rings.

It is spring loaded and should not be stuck but

come out about ¼” and then snap back into

position when released.

Replace safety/relief valves that do not operate

freely with a valve of the same pressure rating.

WARNING: Safety/Relief valve hazards

If the safety/relief valve does not work properly, over-

pressurization may occur causing air tank rupture or

explosion. Occasionally pull the ring on the safety valve

to make sure the safety valve operates freely. If the

valve is stuck or does not operate smoothly, it must be

replaced with a valve having the same pressure rating.

Inspect Air Filter

Inspect the compressor’s air filter on a weekly basis.

A

dirty air filter will not allow the air compressor to operate

at full capacity.

Clean air filter if dirty and restricted air flow.

Replace the air filter every 12 months or 1000

hours.

Note: Do not operate with the air filter removed.

Inspect Compressor for Air Leaks

Inspect system for air leaks on a monthly basis. To test:

Squirt soapy water around joints during

compressor operation and watch for bubbles.

Developing bubbles indicate a leak is present.

Tighten fittings, if necessary.

Summary of Contents for 25653

Page 3: ...3 Appendix A Lubricants and Compatibility 22 Alternate Lubricants 22 Limited Warranty 23 ...

Page 16: ...16 Parts Explosions Model 25653 Rev A Pump not shown on this parts explosion ...

Page 18: ...18 Parts Explosions Model 25654 Rev A Pump not shown on this parts explosion ...

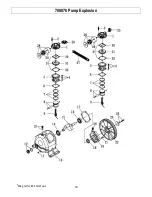

Page 20: ...20 788876 Pump Explosion Wing nut for 28 not shown ...

Page 24: ...24 Assembled by Northern Tool Equipment Company Inc Burnsville MN 55306 NorthernTool com ...