23

Limited Warranty

Dear Valued Customer:

The NorthStar Product you just purchased is built with the finest material and craftsmanship. Use this product properly and enjoy the benefits

from its high performance. By purchasing a NorthStar product, you show a desire for quality and durability. Like all mechanical equipment this

unit requires a due amount of care. Treat this unit like the high quality piece of machinery it is. Neglect and improper handling may impair its

performance. Please thoroughly read the instructions and understand the operation before using your product. Always contact NorthStar

Product Support at 1-800-270-0810 prior to having any service or warranty work performed, as some services performed by parties other than

NorthStar approved service centers may void this warranty. This warranty is in lieu of any other warranty expressed or implied and NorthStar

assumes no other responsibility or liability outside that expressed within this warranty.

Limited Warranty

NorthStar shall warranty any

piece of equipment manufactured, or parts of equipment manufactured, to be free from defects in material or

workmanship for a period of:

NorthStar Warranty

Item #

Consumer Warranty Period

Commercial Warranty Period

25653

25654

4 years from date of purchase by user

2 years from date of purchase by user

“Consumer use” means personal residential household use by a consumer. “Commercial use” means all other uses, including use for

commercial, income producing or rental purposes or when purchased by a business.

This warranty applies to the original purchaser of the equipment (verification of purchase, in the form of a receipt, is the responsibility of the

buyer), is non-transferable, and covers parts and labor. Parts will be replaced or repaired at no charge, except when the equipment has failed

due to lack of proper maintenance. If a part is no longer available, the part may be replaced with a similar part of equal function. Any misuse,

abuse, alteration or improper installation or operations will void warranty. Determining whether a part is to be replaced or repaired is the sole

decision of NorthStar. NorthStar will not provide for replacement of complete products due to defective parts. Any costs incurred due to

replacement or repair of items outside of a NorthStar approved facility is the responsibility of the buyer and not covered under warranty.

Transportation costs to and from service center is the responsibility of the customer.

In addition to the normal warranty, NorthStar shall warrant any normal wear item from defects in material or workmanship for a period of 90

days from the date of purchase by user. Normal wear items include, but are not limited to, belts and filter elements.

This warranty specifically excludes the following; failure of parts due to damage caused by accident, fire, flood, windstorm, acts of God,

applications not approved by NorthStar in writing, corrosion caused by chemicals, use of replacement parts which do not conform to

manufacturer’s specifications, damage related to rodent and/or insect infestation and damage caused by vandalism. Additional exclusions:

loss of running time, inconvenience, loss of income, or loss of use, including any implied warranty of merchantability of fitness for a specific

use. Also, Power Equipment needs periodic parts and service to perform well, and this warranty does not cover instances when normal use

has exhausted the life of a component or the motor.

This warranty does not cover any personal injury or damage to surrounding property caused by failure of any part. Repair or replacement of

parts does not extend the warranty period.

Please fill in the following information and have it on hand when you call in on a warranty claim.

Customer Number: ______________________________________________________________

Date of Purchase: _______________________________________________________________

NorthStar Serial Number: _________________________________________________________

Item Number: __________________________________________________________________

Summary of Contents for 25653

Page 3: ...3 Appendix A Lubricants and Compatibility 22 Alternate Lubricants 22 Limited Warranty 23 ...

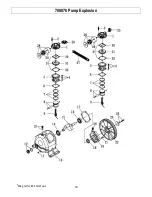

Page 16: ...16 Parts Explosions Model 25653 Rev A Pump not shown on this parts explosion ...

Page 18: ...18 Parts Explosions Model 25654 Rev A Pump not shown on this parts explosion ...

Page 20: ...20 788876 Pump Explosion Wing nut for 28 not shown ...

Page 24: ...24 Assembled by Northern Tool Equipment Company Inc Burnsville MN 55306 NorthernTool com ...