8

Step 3. Select Suitable Location

WARNING: Lifting hazard

The compressor is heavy. Ensure that proper lifting

equipment is available to unload and move compressor

to installation site.

Location Criteria:

Where no flammable vapors, dusts, and gases

are present.

At least 18” away from walls and other objects.

Away from other heat-generating equipment.

Away from dusty/dirty conditions.

In a well illuminated area.

Where proper wire size is already, or can be

made, available.

Positioning:

The compressor should be mounted on a dry,

firm, and level surface. It must sit level and be

stabilized since it will slide or shift during

operation if not secured.

Airflow:

Provide access to adequate, clean and

unobstructed airflow for cooling and air supply.

Remember the supply air is passing through the

compressor supply hoses and tools. These can

be damaged or have a shortened life if unclean

air is present or air filter is not clean and

functioning properly.

Do not allow debris to accumulate or block

airflow.

Do not operate with a tarp, blanket, or cover

surrounding the machine, which blocks air flow.

Do not place any objects against or on top of the

unit, which can also block airflow or damage unit.

Electrical:

MUST be connected to a 115V/230 Volt, single-

phase outlet having operating capacity of 15

amps on 115V or 7.5 amps on 230V.

Wiring:

Proper wire size should take into consideration

length from distribution panel.

Ideal operating temperatures:

40

and 100

F (4

and 37

C).

Operating Limitations:

15

F (-9

C) or above 125

F (52

C).

If temperatures consistently drop below 32

F (0

C),

install within a heated building. If this is not possible,

protect the safety/relief and drain valves from freezing.

Note: Excessive moisture is likely to occur if unit is

stored in an unheated area subject to large

temperature changes. Moisture forming in pump can

produce sludge in the oil, causing parts to wear out

prematurely. Excessive condensation on the pump

when it cools down is a sign that this may be

occurring.

Summary of Contents for 25653

Page 3: ...3 Appendix A Lubricants and Compatibility 22 Alternate Lubricants 22 Limited Warranty 23 ...

Page 16: ...16 Parts Explosions Model 25653 Rev A Pump not shown on this parts explosion ...

Page 18: ...18 Parts Explosions Model 25654 Rev A Pump not shown on this parts explosion ...

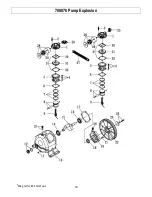

Page 20: ...20 788876 Pump Explosion Wing nut for 28 not shown ...

Page 24: ...24 Assembled by Northern Tool Equipment Company Inc Burnsville MN 55306 NorthernTool com ...