9

Operation

Follow Operation Safety Rules

Before starting the compressor, review the safety rules

found below and throughout the manual.

WARNING

Failure to follow safety rules may result in serious injury

or death to the operator or bystanders.

Instruct Operators

. Owner must instruct all operators in

safe set-up and operation. Do not allow anyone to

operate the compressor who has not read the

Owner’s Manual.

Safety Guarding

. Only operate with safety covers,

guards and barriers secured and in good working

order.

Moving Parts

. Keep hands, feet, hair and apparel away

from moving parts. Never remove any guards while

the unit is operating. Do not reach into an air vent or

cavity, as they may cover dangerous moving parts.

Ear Protection.

Hearing can be damaged from

prolonged, close-range exposure to the noise level

produced by this compressor. Ear plugs or other

hearing protection is recommended for persons

working who are exposed within 15-20 feet of the

running compressor for an extended period of time.

Eye Protection.

Wear ANSI/OSHA required “Z87.1”

safety glasses when operating or servicing the

compressor.

Pressurized air spray from this unit can

cause severe injury to the eyes. Also, small objects

will become airborne as the air spray contacts them.

Respirator.

Wear a respirator when using the

compressed air for spraying. Spray in a well-

ventilated area to prevent health and fire hazards.

Prepare for Operation

Make sure that any regular maintenance has been

performed as prescribed in the

“Maintenance & Repair”

section.

Drain receiver tank of any moisture.

Inspect for oil leaks.

Check for any unusual noise/vibration.

Ensure the area around compressor is free from

rags, tools, debris and flammable or explosive

materials.

Ensure belt guards and covers are securely in

place.

WARNING: Entanglement hazard

Do NOT operate with protective covers or guards

removed. Beneath these covers are high speed moving

components, which can entangle the operator or

bystanders. Entanglement in this equipment may result

in serious injury, amputation or death.

Check/Add Oil to the Pump

Check the oil level in the pump. Use sight glass for

pump oil level. Add oil as needed.

WARNING: Burn hazard

Never open oil port while compressor is running. Hot oil

can spray over face and body.

CAUTION: Inadequate lubrication hazard

Never operate compressor with inadequate lubricant.

This will cause overheating and severe damage to the

engine and pump.

Figure 4

The compressor pump capacity is 16.9 oz. Use SAE 30

non-detergent pump oil (part #4043) prior to break-in.

You may use synthetic lubricants after 50 hour break-in.

See “

Lubricants and Compatibility

” for a list of suitable

and alternative lubricants.

CAUTION: Synthetic lubrication damage

If you will be using a synthetic lubricant, all downstream

piping material and system components must be

compatible.

Oil Cap

Sight

Glass

Drain

Plug

Breather Cap

Summary of Contents for 25653

Page 3: ...3 Appendix A Lubricants and Compatibility 22 Alternate Lubricants 22 Limited Warranty 23 ...

Page 16: ...16 Parts Explosions Model 25653 Rev A Pump not shown on this parts explosion ...

Page 18: ...18 Parts Explosions Model 25654 Rev A Pump not shown on this parts explosion ...

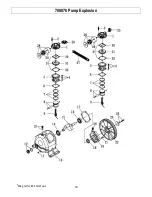

Page 20: ...20 788876 Pump Explosion Wing nut for 28 not shown ...

Page 24: ...24 Assembled by Northern Tool Equipment Company Inc Burnsville MN 55306 NorthernTool com ...