10

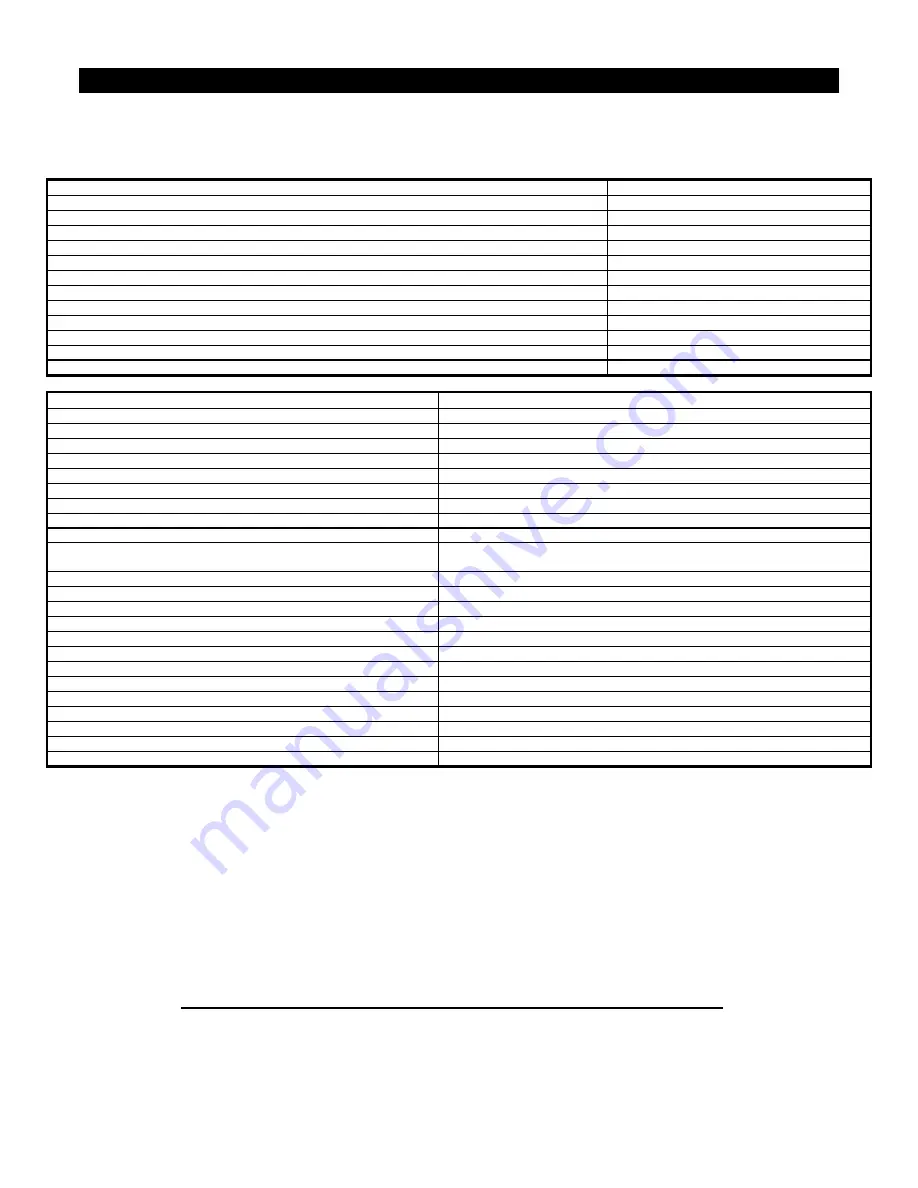

Troubleshooting

This section provides a list of the more frequently encountered compressor malfunctions, their causes and

corrective actions. Some corrective actions can be performed by the operator or maintenance personnel,

and others may require assistance of a qualified electrician or Service Center.

PROBLEM

POSSIBLE CAUSE

Engine does not start.

A,B,C,D,E

Air delivery drops off.

H, I, J, L, M, N, P

Compressor does not come up to speed.

F, G, J, K

Compressor is slow to come up to speed.

F, G, J, K, L

Compressor will not unload cycle.

H, L, N, P

Compressor will not unload when stopped.

H, L, N, P

Excessive starting or stopping.

N, Q, S

Moisture in crankcase, “milky” substance in oil.

R

Oil in discharge air.

T

Safety/relief valve

“pops”.

L, M, N

Low interstage pressure.

W

High interstage pressure.

V

POSSIBLE CAUSE

POSSIBLE SOLUTION

A.) Low Oil Shutdown

Fill engine with the adequate amount of oil.

B.) Cold Engine

Choke engine to start.

C.) No Fuel

Add gas to engine. Make sure fuel shutoff valve is open

D.) Engine not turned ON

Place ON/OFF switch in the ON position.

E.) Spark plug wire not attached

Attach spark plug wire to spark plug.

F.) Compressor viscosity too high for ambient temperature.

Drain existing lubricant and refill with proper lubricant.

G.) Belt tension too tight or sheaves not aligned.

Check tension/ alignment.

H.) Air leaks in discharge piping.

Check tubing connections, Tighten joints or replace as required.

I.) Compressor components leaky, broken, loose.

Inspect components. Clean or replace as required.

J.) Loose flywheel or motor pulley, excessive end play in motor shaft

or loose drive belts.

Check flywheel, motor pulley, crankshaft drive belt tension/alignment.

Replace or repair as required.

K.) Leaking check valve or check valve seat blown out.

Replace check valve.

L.) Clogged or dirty inlet and/or discharge line.

Clean or replace.

M.) Defective safety/relief valve.

Replace.

N.) Pressure switch unloader leaks or does not work.

Realign stem or replace.

O.) Inadequate ventilation around flywheel.

Relocate compressor for better air flow.

P.) Leaking, broken or worn inlet unloader parts at check valve.

Inspect parts and replace as required.

Q.) Excessive condensation in receiver tank.

Drain receiver tank.

R.) Detergent lubricant in crankcase.

Replace with proper lubricant.

S.) Light duty cycle.

Increase duty cycle.

T.) Lubricant level too high.

Drain excess lubricant.

U.) Worn cylinder finish.

Deglaze cylinder with 180 grit flex-hone.

V.) Low pressure inlet valve leaking.

Inspect, clean or repair as required.

W.) High pressure inlet valve leaking.

Inspect, clean or repair as required.

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar Product Support 1-800-270-0810