6

00882

Maintenance

WARNING!

Disconnect spark plug wire from spark plug and release air pressure from system before performing

maintenance.

NOTE:

All compressed air systems contain maintenance parts (e.g. lubricating oil, filters, separators), which are

periodically replaced. These used parts may be, or contain, substances that are regulated and must be disposed

of in accordance with local, state, and federal laws and regulations.

NOTE:

Take note of the position and locations of parts during disassembly to make reassembly easier. The

assembly sequences and parts illustrated may differ for your particular unit.

Daily or before each

operation

Check lubrication levels. Fill as needed.

Drain receiver tank condensation.

Check for unusual noise or vibration.

Ensure belt guards and covers are securely in place.

Ensure area around compressor is free from rags, tools, debris, and flammable or explosive

materials.

Weekly

Check safety/relief valves by pulling rings. Replace safety/relief valves that do not operate freely.

Inspect air filter element. Clean if necessary.

Monthly

Inspect for air leaks. Squirt soapy water around joints during compressor operation and watch for

bubbles. Tighten fittings if necessary.

Clean exterior.

3 months or 500

hours

Change petroleum lubricant while crankcase is warm.

12 months or 1000

hours

Replace air filter element.

INSTALLING OIL DRAIN PORT

1. Place an oil pan below port before unscrewing oil drain plug.

2. Remove plug (bolt and washer) from crankcase.

Quickly screw in stub.

3. Install bolt and washer into stub after changing oil, or

remove stub and reinstall plug into port.

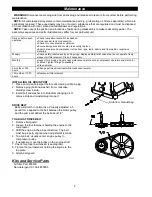

DRIVE BELT

Belts will stretch in normal use. Properly adjusted, a 5

pound force applied to the belt between the motor pulley

and the pump will deflect the belt about 1/2”.

TO ADJUST DRIVE BELT:

1. Remove belt guard.

2. Loosen the four fasteners holding the engine to the

compressor.

3. Shift the engine in the proper direction. The belt

must be properly aligned when adjustment is made.

4. To align belt, visually center engine pulley to

compressor pulley.

6. If necessary, move the pulley on the engine shaft.

7. Check for proper belt tension (see diagram).

8. Tighten the four fasteners holding the engine to the

top plate.

9. Attach belt guard.

Kits and Service Parts

Air filter: Part #35409

Non-detergent Oil: Part #35605

Stub from manual bag