Page 7

ELECTRICAL INSTALLATION

1

2

3

4

5

6

7

8

9

10

Black

Green

Blue

Violet

—

Red

Yellow

Gray

Orange

Braid

A

E

D

C

—

B

H

G

I

J

* Index (Z) optional. See Ordering Information

Common

B

A

Z *

N/C

Vcc

—

B

—

A

—

Z *

Shield

ELECTRICAL CONNECTIONS

Signal

Connector Pin

Pigtail Cable

MS 3102E18-IT#

Electrical connections are made to the sensor

module through a standard 1/2 inch NPT liquid tight

flexible conduit. The nipple length may be changed

to extend the outlet box if desired. Interconnection

cable recommendations are as follows: stranded

copper, 22 through 16 gage, braided or foil with

drain wire shielding 0.05 mF maximum total mutual

or direct capacitance, outer sheath insulated. Shrink

tubing may be placed over any wires without

insulation. For lengths over 100 feet, use 18 gage

or larger, to a maximum of 1000 feet. If shielded

twisted pair wire is used, do not cross channels.

Keep each pair of complementary channel outputs

together in a single twisted pair (e.g., A and A

complement).

5.0 Wiring

NOTE: Refer to “Important Installation Informa-

tion” on pages 2 & 3 prior to wiring the encoder.

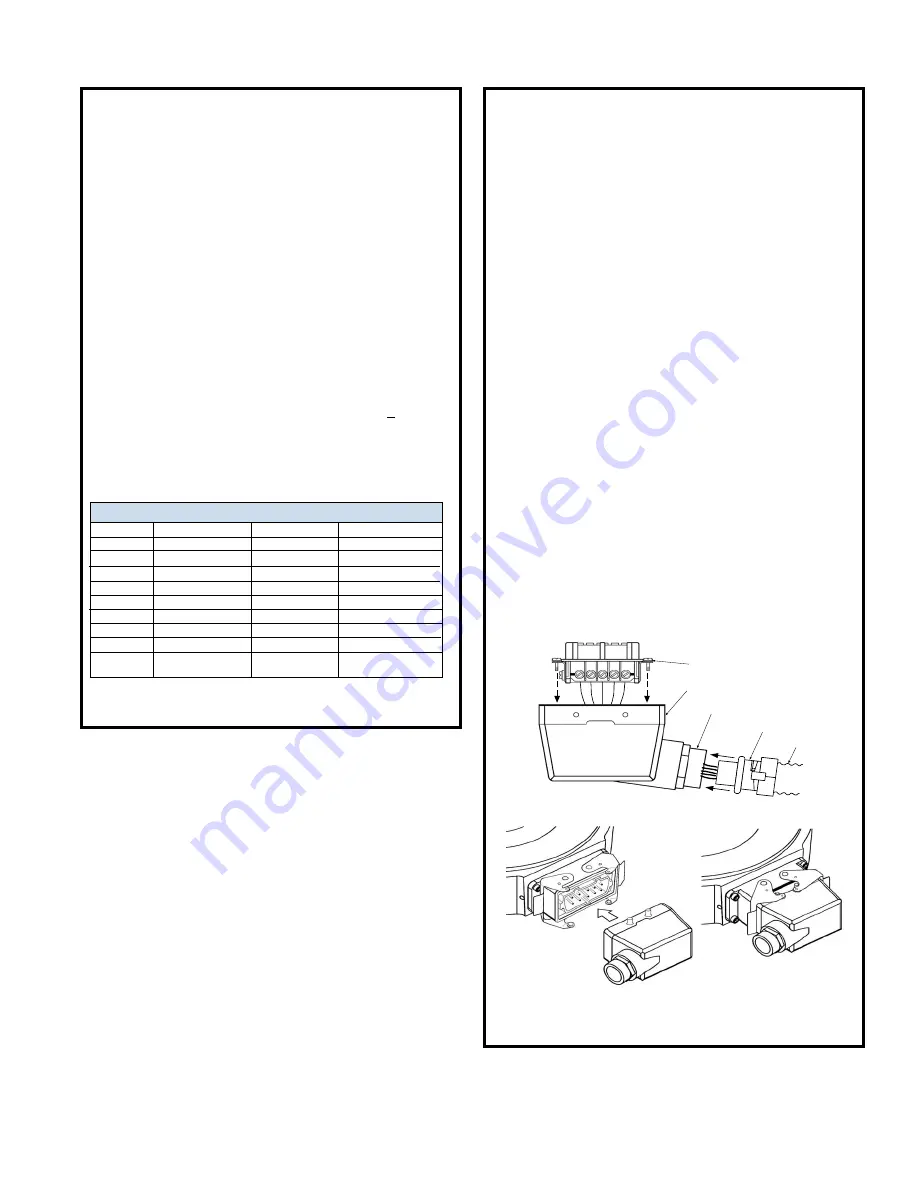

5.1 Quick Release Connector Hood

Wiring

To install the Quick Release Connector, perform the

following steps.

1. Remove the four screws from the mating connec-

tor housing that hold the terminal block in place.

Remove terminal block from housing.

2. Insert wiring through liquid tight flexible seal and

mating connector housing. Leave enough wire

exposed to comfortably reach the terminal block.

Wire to terminal block according to wire code in

Table 1. A similar wiring list is attached to enclosure.

NOTE There are two orientations of the connec-

tor hood. The terminal block can be inserted

either way so the connector hood points up or

down. Choose the direction best for your

application.

4. Tighten Liquid Tight fitting on housing. OP-

TIONAL: In some hostile environments, seal

between connector body and

Sensor Module can

be improved by smearing a sealant (silicone

grease, etc.) on the neoprene seal of the connector.

5. Mate connector into place on sensor mount and

snap the two latches into place. If only one sensor

is being installed, ensure cover plate is installed

over other sensor hole.

Terminal Block

1/2 inch NPT

Mating Connector Housing

Liquid Tight Fitting

Conduit

Quick Release Hood Wiring