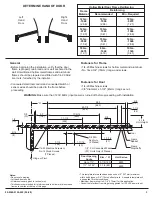

Standard Duty Double Lever Arm Application for Frame Reveals to 6-7/8” (175mm)

Stop (Push) Side of Door Installation For Handed (Not Reversible) Units

Door Openings 85° to 110° Use Series 6920 / 6921

Door Openings 111° to 180° Use Series 6930 / 6931

80-9369-0120-020 (09-08 )

Right Hand Door

Left Hand Door

80-9369-0120-020 (09-08)

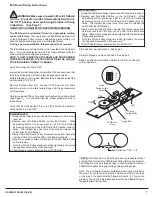

WARNING

120 VOLT POTENTIAL PRESENT. MAKE SURE

POWER IS TURNED OFF DURING

INSTALLATION PROCEDURE.

An incorrectly installed or improperly

adjusted door operator can cause property

damage or personal injury. These

instructions should be followed to avoid the

possibility of misapplication or

misadjustment.

CAUTION

CAUTION

AmericansWith Disabilities Act (A.D.A.)

ANSI Standards

ANSI A117.1

providing

accessibility and usability for physically

handicapped people"

• ANSI A156.19

"for power assist and low energy power

operated doors"

U.L. Listing

Underwriters Laboratories, Inc. listed for use on

fire and smoke barrier door assemblies when the

120VAC (60Hz) power input is supplied through

the normally closed alarm contacts of a

compatible U.L. Listed alarm system or alarm

panel.

These door operators can be installed and adjusted to conform with

A.D.A. regulations.

– These door operators permit door

assemblies to conform to the requirements of this

specification "for buildings and facilities –

.

– These products are designed to conform to this

specification

.

– "PAS" Function is designed to meet or exceed all of the

requirements for the "Power Assist Door".

– "POR" Function is designed to meet or exceed all of the

requirements for the "Low Energy Power Operated Door".

C

US

UL

®

6900 PowerMatic

®

Low Energy Power Operator

Installation Instructions

Activation Modes (Modes are configured during installation.)

• Selectively Activated Mode -

• Automatically Activated Mode -

Functions (Functions are configured during installation.)

• Power Assist function (PAS)

unit depends upon external

switches or scanners for activation of functions.

unit will operate

utilizing on-board

ELS switching that automatically activates the functions. External

switches or scanners may also be used for activation.

– The unit operates as a standard

door closer unless activated via one of the Modes listed above.

Upon activation the door opening resistance is reduced, for a

selected period of time, well below A.D.A. guidelines. When the

time period expires, the door closes under normal door closer

spring power.

with a slight

movement of the door toward the open position

– The unit performs as a low

energy power door operator. Field settings allow for following two

functions:

1. Selectively Activated Mode (See Above).

2. Automatically Activated Mode (See Above).

• Power Operator function (POR)

NOTE: The

are factory set in the

as a

ELS Board Dip Switches

Selectively Activated Mode

Power Operator Function.

Basic Requirements

Parts Identification

Installation Template

Installation Sequence

Regulation & Adjustment

General Product Information

Function and Operation Sequence

ELS “Timing” Calibration

ELS Reset Instructions

Troubleshooting

2

2

3

4

5

6

6

7

8

8