80-9369-0120-020 (09-08)

• U.L. labeled fire or smoke barrier door assemblies require that

the 120VAC (60Hz) power input to the PowerMatic™ door

operator be supplied through normally closed alarm contacts of

the alarm system/alarm panel.

• Power input to PowerMatic door operator must be 120 VAC

(60Hz) to terminals HOT and COM at terminal strip T1. Terminal

GND is earth ground.

• All wiring must conform to standard wiring practice in

accordance with national and local wiring codes.

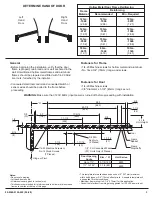

• Note: Unless otherwise noted, all dimensions are given in

inches (millimeters).

• Minimum frame face 2" (51mm).

• Minimum ceiling clearance 4-1/8” (105mm).

• Minimum suggested and required material thickness for hollow

metal frames (skin plus reinforcement) is charted on page 3.

• For wiring refer to Wiring Instruction 80-9369-0901-020.

• Hand of unit and hand of door must be the same. Hand of unit is

not reversible.

• Door must be hung on butt hinges [5" (127mm) max. width] or

3/4" (19mm) offset pivots. A separate door and frame

preparation template will be supplied for other conditions.

• Door thickness must be 1-3/4" (44mm) minimum, 2-1/4" (57mm)

maximum.

• Door must swing freely through the entire opening and closing

cycle before beginning the installation.

• Use of a supplemental door stop is always recommended.

Requirements

2

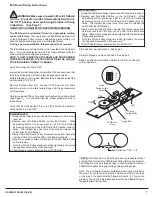

SC

SC

XX

XX

XX

PAS

DN

T2

T1

Sw3

ELS

Dip

Switches

Pinion Timing

Pulley

Timing Belt

ELS Board w/

ELS Board Pulley

ELS Board

LED

JP2

Terminal

Strip

Rotary Switches / Timer Pots

See Pages 2 and 4 of

Wiring Instructions

80-9369-0901-020

1

2

3

4

OFF

ON

Sw1

Dip

Switches

Main Board

Bracket for

Input Power

Terminal Strip

T1

Jp1

Terminal

Strip

Jp4

Terminal

Strip

Jp5

Terminal

Strip

Jp3

Terminal

Strip

(Sc) Speed

Control Valve

Solenoid

Door Calibrate

Close Position

Door Calibrate

Open Postion

11/16” Power

Adjustment Nut

Hand

Marking

(B)

Backcheck

Valve

(S)

Sweep

Speed Valve

(L)

Latch

Speed Valve

Selector Mode

Switch

“OFF” “ON” “H/O”

(P)

Backcheck

Position Valve

(PA)

Pressure

Adjustment Valve

11/16" Power

Adjustment Nut

S

L

PA