Page

30

/

48

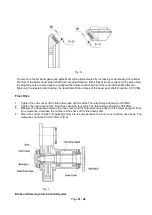

Adjusting the Spiral Bevel Pinion Shaft

After pre-tightening the tapered roller bearing of the spiral bevel pinion shaft, the measured total friction

torque of the spiral pinion shaft should be 1.0-1.5mm (see Fig. 6).

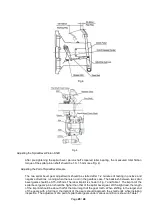

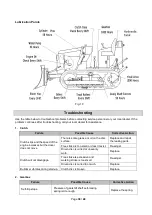

Adjusting the Pair of Spiral Bevel Gears

Begin adjusting the pair of spiral bevel gears after 1-2 minutes of testing in positive and negative directions,

running when there is no oil in the gearbox case. The backlash between two spiral bevel gears should be 0.15-

0.25mm. The ideal imprint is shown in Fig. 7 and Table 1. The imprint of the spiral bevel gears

’ pinion should

be higher than that of the spiral bevel gear. With a light load, the length of the imprint should be about half of

the total length of the gear tooth. While shifting to the larger end of the gears with a full load, the imprint of the

gears should approach the small end while installing inspection. The adjustment of a pair spiral bevel gears

under various conditions are shown below.

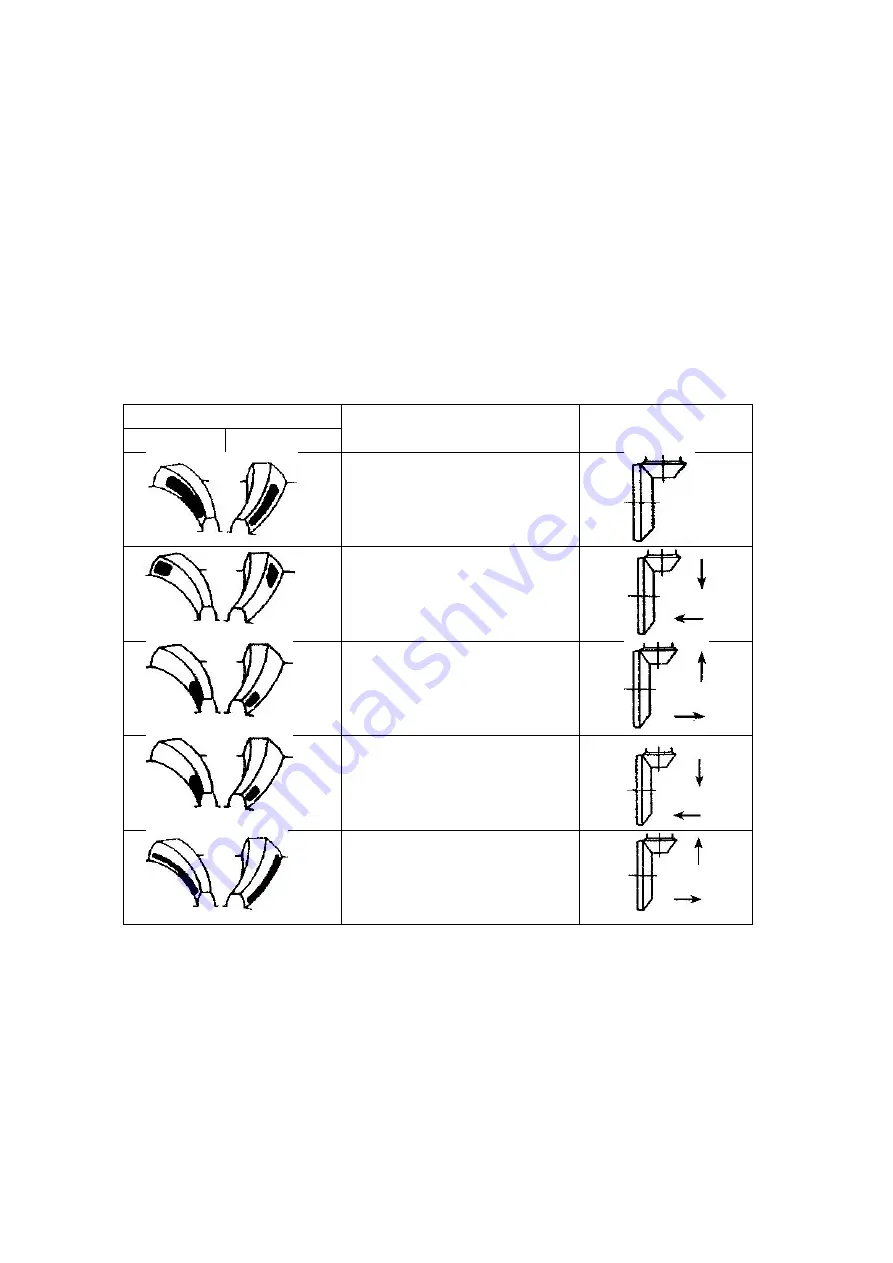

Imprints

Adjusting Method

Gears Directions

Pinion

Bevel Gear

Normal imprint (ideal imprint).

Move the bevel gear off the pinion.

If the backlash is too big, move

pinion inward.

Move the bevel gear close to the

pinion. If the backlash is too small,

move the pinion outward.

Move the pinion close to the bevel

gear. If the backlash is too small,

move the bevel gear outward.

Move the pinion off the bevel gear.

If the backlash is too big, move the

bevel gear inward.

Table 1: Adjusting Imprints and Backlash of Spiral Bevel Gear

Summary of Contents for 40XTD

Page 12: ...Page 12 48 7 8 9 10 11 12 13 14 15 16 17...

Page 13: ...Page 13 48 18 19 20 21 22 23 24 25...

Page 43: ...43 48 Fig 11 Fig 12...