Page 46 of 48

Limited Warranty

The 40XTD Bulldozer is sold by NorTrac; a division of Northern Tool & Equipment Company, Inc. (NTE).

NorTrac will repair or replace, at its option, any part(s) thereof of the NorTrac 40XTD Bulldozer that are shown

to be defective in material and/or workmanship, under normal use during the applicable 24-month warranty

period. NorTrac wants your equipment to operate well and will assist you on repairs.

All warranty repairs

submitted after the first 60 days of ownership are subject to a $100.00 labor deductible, per covered

repair.

After the labor deductible has been met, all warranty repairs and replacements will be made without

charge for parts or labor at a pre-authorized service center. All parts replaced as a result of this limited

warranty become the property of NorTrac and must be returned to NTE upon request. All parts replaced will

become a portion of the whole and will be warranted for the duration of the original equipment warranty.

Length of Warranty

The limited warranty begins on the original date of purchase and extends to 24 months for consumer

household use. For the commercial end user, the limited warranty continues for 6 months (180) days from

date of original purchase. Commercial use is defined as: intended for the purpose of monetary reward or gain

through the loan, rental or hire of equipment - OR- any manner that is primarily intended for or directed toward

commercial advantage “For Profit” or private monetary compensation or use by any governmental agency.

Qualifications for Limited Warranty

This applies to the original purchaser of the equipment. The limited warranty is non-transferable. Owner is to

provide proof of purchase. Equipment was purchased in the United States from authorized representatives of

NorTrac and/or NTE, Company, Inc.

To Obtain Service

Contact NorTrac Warranty Administrator by calling 1-800-521-0438 to report a possible warranty issue and to

receive repair authorization from the Warranty Administrator. Detailed failure information can also be provided

in hard-copy written form along with contact information to the address listed at the bottom of this page.

After receiving authorization from NorTrac Warranty Administrator, and the address of the pre-authorized

service center, take the equipment to the service center during their regular business hours.

All

transportation costs after the first 60 days of ownership, are the responsibility of the equipment

owner.

Exclusions and Warranty Disclaimers

This limited warranty applies to equipment used in its original form. Any unauthorized modifications or any

incorporation or use of unsuitable attachments or parts will automatically void this limited warranty. This

limited warranty does not include parts affected or damaged by accident and/or collision, normal wear & tear

(light bulbs, filters, belts, motor brushes, brakes, fuses and switches, tires and tubes, clutch linings, engine

tune up, wheel alignment and lubrication), fuel contamination, or from failure to follow instructions contained in

the User Manual for the equipment. Warranty is void if adjustments are made to the injection pump fuel

delivery system, starting fluid or ether is used to start or run the engine or regular maintenance and service is

not performed as prescribed by the operator’s manual during the warranty term. The cost of normal

maintenance of the equipment is the responsibility of the owner.

EXCEPT FOR THE EXPRESS WARRANTIES SET FORTH IN THIS SECTION, NEITHER NORTRAC NOR

NTE COMPANY, INC. MAKE ANY REPRESENTATIONS AND GRANT NO WARRANTIES, EXPRESS OR

IMPLIED, EITHER IN FACT OR BY OPERATION OF LAW, BY STATUTE OR OTHERWISE, AND BOTH

NORTRAC AND NTE COMPANY, INC. SPECIFICALLY DISCLAIM ANY OTHER WARRANTIES, WHETHER

WRITTEN OR ORAL, OR EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF QUALITY,

MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE OR PURPOSE OR ANY WARRANTY AS TO

THE VALIDITY OF ANY PATENTS OR THE NON-INFRINGEMENT OF ANY INTELLECTUAL PROPERTY

RIGHTS OF THIRD PARTIES.

Limited Warranty

This limited warranty does not cover defects that result from accident, misuse, lack of maintenance, improper

repairs, neglect or use of replacement parts and accessories which do not meet NorTrac specifications.

Disclaimer of Consequential Damage

In no event will NorTrac or NTE Company, Inc. be liable for any loss of income, loss of time or use of the

product, transportation, hiring of alternative services, commercial loss or any other incidental, consequential,

indirect, or special damages and / or expenses. Some states do not allow limitations on how long an implied

warranty lasts and / or do not allow the exclusion or limitation of incidental or consequential damages, so the

above exclusions and limitations may not apply to you. This limited warranty gives you specific legal rights

which may vary from state to state.

Summary of Contents for 40XTD

Page 12: ...Page 12 48 7 8 9 10 11 12 13 14 15 16 17...

Page 13: ...Page 13 48 18 19 20 21 22 23 24 25...

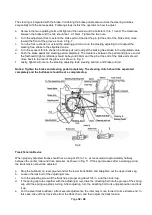

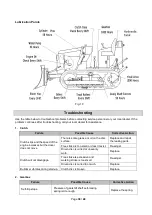

Page 43: ...43 48 Fig 11 Fig 12...