LineTro110Tµr User Guide

June 2011 Page 11 of 16

5.

MAINTENANCE

It is advisable to inspect the indicator once a

year or 1 year after it was last activated. The

inspection should include a functional test

with a magnet to show that the flash

frequency and intensity are normal.

5.1.

Battery replacement

The battery

is fitted into the top cap of the

indicator housing. To replace the battery,

first disconnect the battery from the

electronics board by pulling the battery plug,

then pull the battery from the top cap. Fitting

a new battery is the reverse of the removal

procedure.

The spare battery, KBB-11, comes with a

connector so the replacement can be carried

out on-site.

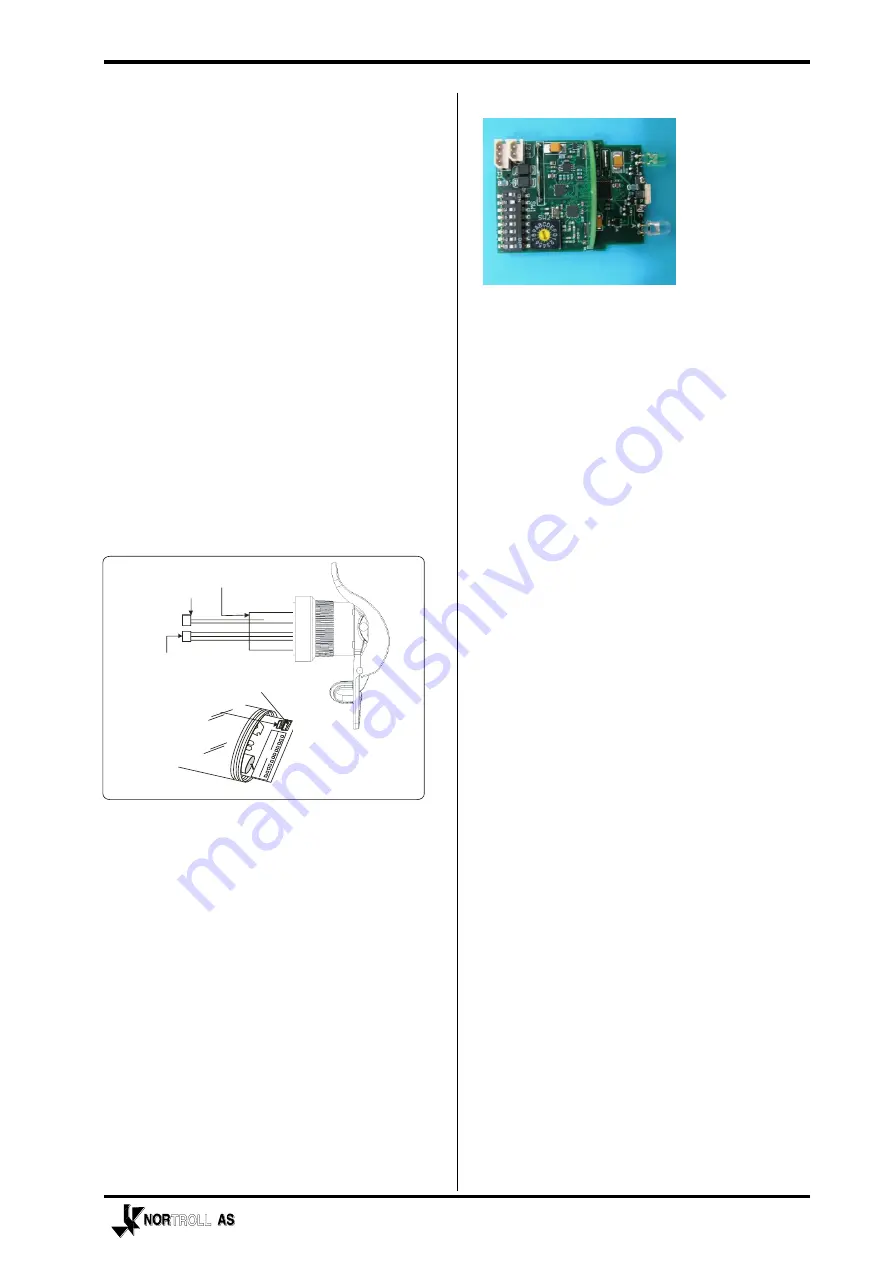

NEGATIVE POLE

OF THE BATTERY

BATTERY CONNECTOR

BATTERY CONNECTOR

SENSOR

CONNECTOR

SENSOR CONNECTOR

o

p

e n

Figure 10: LINETROLL 110Tµr connectors

5.2.

Reset battery monitoring

When the battery is replaced with a new

battery, the battery monitoring must be reset.

With the battery disconnected reset can be

done setting Rotary switch to position.

(see

figure 11b.)

while at the same time powering

the indicator by connecting the battery.

The indicator will confirm the reset with a

continuous green flashing. Unplug the

battery and then plug the batter in again.

LineTroll 110Tµr

Figure 11b. Rotary switch in location 0 for resetting

battery counter on LineTroll 110Tµr.

2009

The indicator battery monitoring has now

been reset, and the green led will stop

flashing.

6.

INDICATOR HOUSING

The indicator housing is made of high

strength plastics. The material is highly UV

stabilised and is flame retarding.

The lens material, in addition, has excellent

optical characteristics.

An O-ring joint is used to provide a good

seal between the upper cap and the lens.

The line clamp is made of PA (Poly Amid).

The top cap of the

indicator has a colour-

coded label indicating the year of

manufacture. See

Figure 11Figure 11: Top-cap

colour coding versus the year of manufacture