LineTro110Tµr User Guide

June 2011 Page 4 of 16

2.1.

Sensors

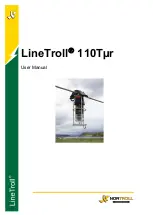

The magnetic field generated by the line

current induces a signal in the indicators

pickup coil. The induced signal is applied to

a di/dt sensor in order to discriminate

between fault current and load current.

The di/dt sensor detects instantaneous

current level increases, as is the case when a

faults occurs.

The trip level of the di/dt sensor can be set to

+500A or +1000 A by means of a switch

bank inside the unit.

A normal variation of the load current will

not activate the LINETROLL 110T

r.

Figure 1: Magnetic field sensor principle.

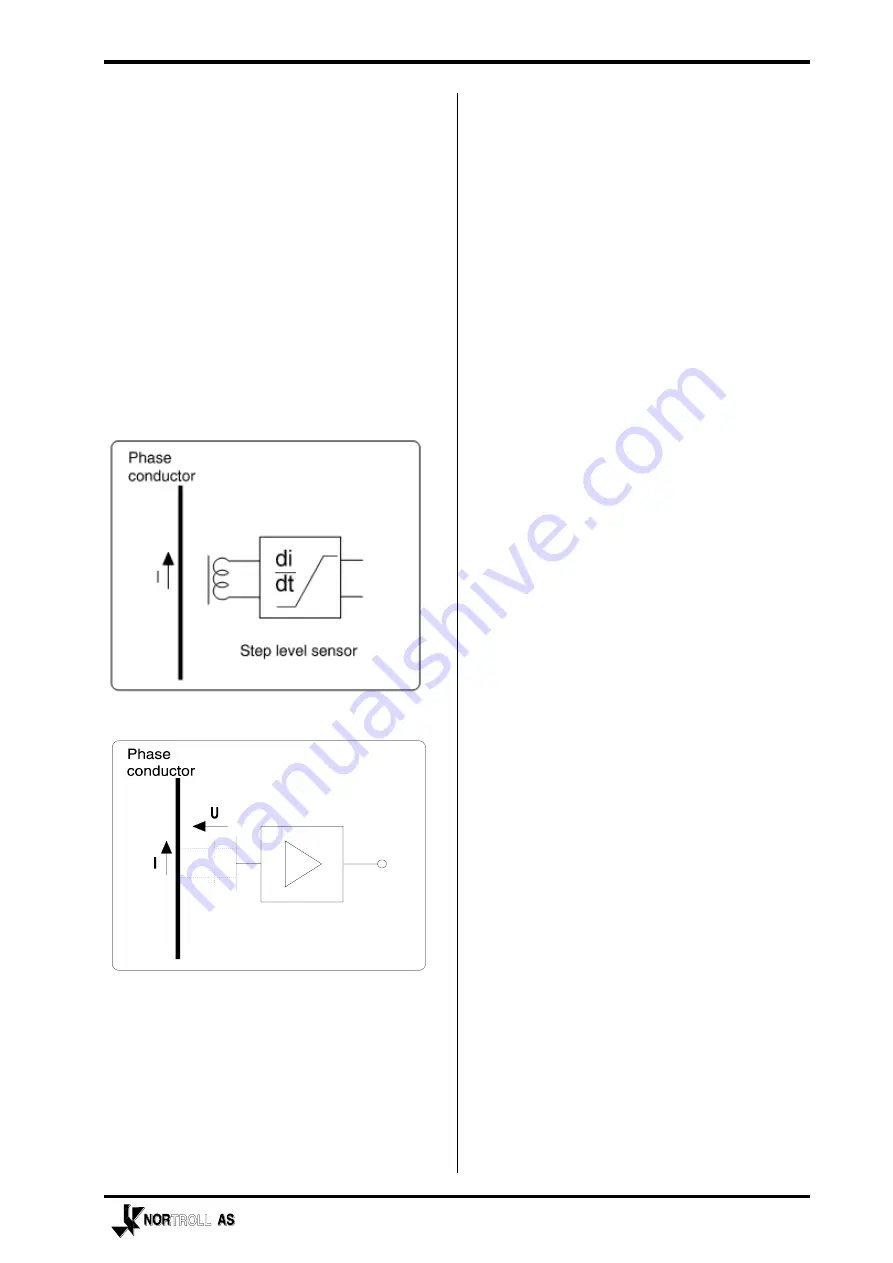

Figure 2: Electric field sensor principle

The line voltage is detected by means of an

antenna housed inside the indicator.

2.2.

Activation criteria

The LINETROLL 110T

r can be easily set

to operate in the wanted mode by altering a

number of switches inside the unit.

In order to avoid activating the indicator due

to magnetising inrush current, it's di/dt

sensor is blocked for 5 sec upon energising

of a line. While the blocking time elapses,

the line current can stabilise so as not to

cause triggering of the di/dt sensor.

A fault duration exceeding 60ms is required

to activate the indicator.

In addition to its di/dt sensor, the

LINETROLL 110T

r incorporates a

common threshold sensor, with threshold

levels of 500A, or 1000A. The threshold

criterion, if enabled, activates the indicator if

a fault current exceeds the selected level.

(Inrush blocking is still active in this mode)

A rapid line current increase followed by a

de-energising of the line within 5 sec will

activate the indicator.

2.3.

Indication

The main mode of local indication is 1 super

intensive red LEDs which indicate for

permanent faults.

Secondary indication is a single regular

green LED.

For a transient fault: The green LED

flashes for 24h (no red LED’s flash).

For a permanent fault: The super

intensive red LEDs flash until reset

(timer, auto or manual reset).

* Note: to verify a permanent fault is

present, the red LED indication is delayed

70 sec. See more detailed info in

Ch 10

Flashing sequence.