NSJ0202 2 Ton Capacity Aluminum Service Jack User Manual

2

rev. 11/29/17

INSPECTION

Visual inspection should be made before each use over the life of the jack, checking for leaking hydraulic fluid and damaged, loose or

missing parts. Any jack which appears to be damaged in any way, is found to be badly worn, or operates abnormally MUST BE REMOVED

FROM SERVICE until necessary repairs are made.

SETUP

1. Depress the upper handle lock in the upper handle while simultaneously inserting the end of the upper handle in the lower handle.

Rotate the upper handle back and forth until the handle lock seats in the lower handle lock hole.

2. Unscrew the handle socket bolt so that it will not interfere with the insertion of the handle in the handle socket. Insert the handle in the

handle socket and rotate the handle assembly back and forth until the release valve fits in the receiver in the bottom of the handle.

Secure the handle in the handle socket by tightening the handle bolt.

3. Sometimes air gets trapped in the hydraulic system during shipping and handling. If the pump feels spongy, or there is not a full

incremental pump stroke, or the jack will not raise to maximum height, follow these instructions in order to purge air from the system:

a. With the lift arm in its completely retracted position and the pump handle rotated all the way in a clockwise direction until it stops,

rotate the pump handle in a counterclockwise direction two full revolutions.

b. Proceed to pump the jack 15 full incremental pump strokes.

c. Rotate the pump handle clockwise until it stops and proceed to pump the handle until the lift arm reaches maximum height.

d. Repeat steps "A" through "C" until all air is purged from the system.

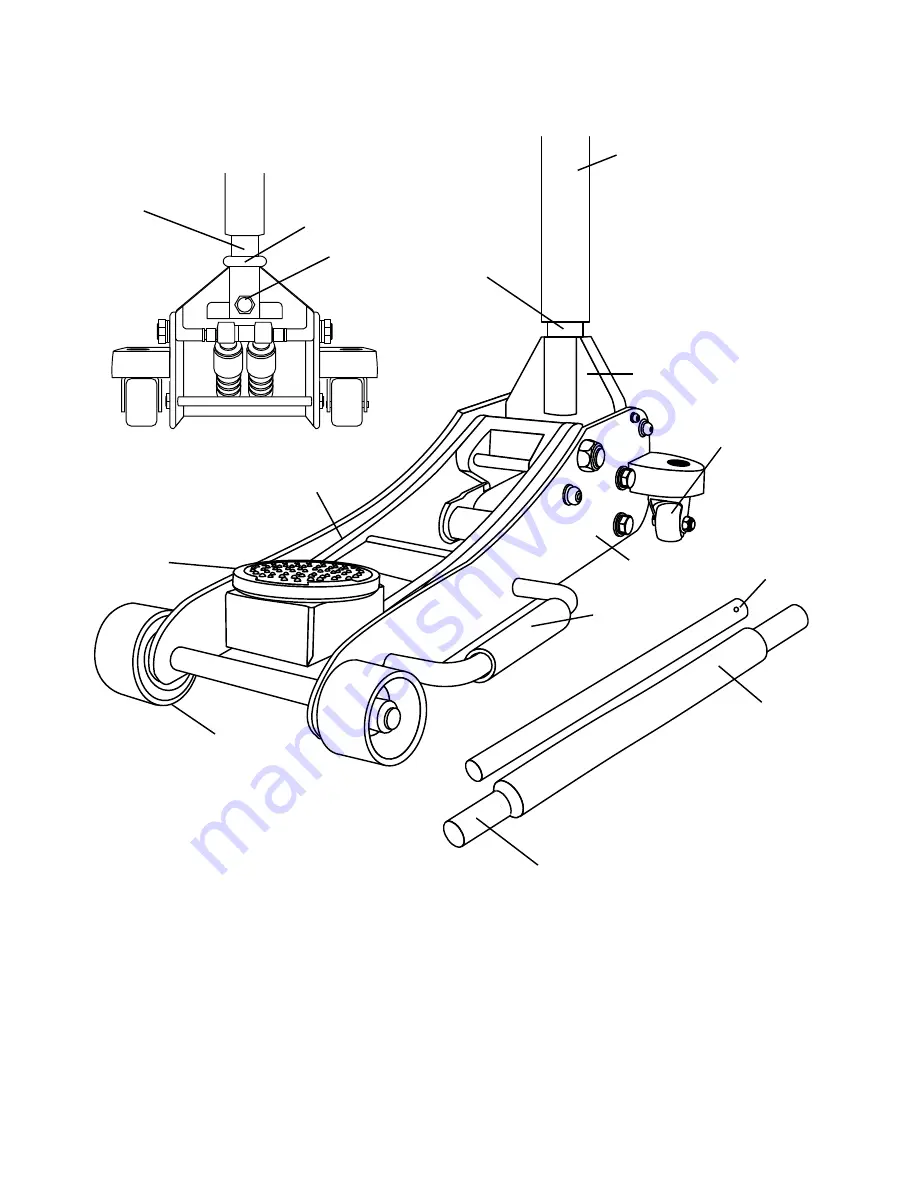

Handle

Handle Socket

Bolt

Handle

Socket

Upper

Handle

Lock

Lower

Handle

Pad

Lower Handle

Side

Handle

Pad

Saddle

Handle

Pad

Handle

Socket

Handle

Rear

Casters

Chassis

Front

Wheels

Lift Arm