4135 English, rev 3

17

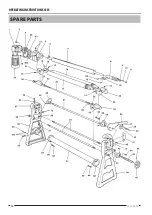

spare parTs

Svenska

English

Deutsch

Francais

1

1

Snäckväxel

Worm gear

Schneckengetriebe

Engrenage à vis sans fin

2

4

Skruv

Screw

Schraube

Vis

3

1

Lock för växelhus

Cover for gearbox

Abdeckung für Getriebe

Couvercle de boîte de vitesses

4:01

1

Kugghjul

Gear

Zahnrad

Roue dentée

4:02

1

Kugghjul

Gear

Zahnrad

Roue dentée

5

1

Växelhus

Gearbox

Getriebegehäuse

Boîte de vitesse

6

1

Kil

Wedge

Keil

Coin

7

1

Övervals

Top roll

Oberwalze

Rouleau supérieur

8

1

Hylsa med styrning

Sleeve with guide

Buchse mit Führung

Douille avec guide

9

1

Ändbricka

End washer

Endplatte

Disque

10

1

Spännstift

Roll pin

Spannstift

Goupille de serrage

11

1

Skruv

Screw

Schraube

Vis

12

4

Skruv

Screw

Schraube

Vis

13

1

Lagerhus

Bearing housing

Lagergehäuse

Boîte de palier

14

1

Kil

Wedge

Keil

Coin

15

8

Smörjnippel

Grease nipple

Schmiernippel

Graisseur

16

1

Böjvals

Bending roll

Biegewalze

Rouleau arriére

17

1

Undervals

Lower roll

Unterwalze

Rouleau inférieur

18

1

Styrning

Guide

Führungen

Guide

19

1

Smörjnippel

Grease nipple

Schmiernippel

Graisseur

20

1

Lagerhus

Bearing housing

Lagergehäuse

Boîte de palier

21

1

Lagerhus

Bearing housing

Lagergehäuse

Boîte de palier

22

1

Kil

Wedge

Keil

Coin

23

6

Mutter

Nut

Mutter

Ecrou

24

1

Axel

Axle

Achse

Axe

25

1

Ok

Support

Stütze

Support

26

1

Lagerhus

Bearing housing

Lagergehäuse

Boîte de palier

27

1

Kil

Wedge

Keil

Coin

28

1

Mutter

Nut

Mutter

Ecrou

29

1

Stoppskruv

Stop screw

Stellschraube

Vis d’arrêt

30

1

Excenter

Eccentric

Exzenter

Excentrique

31

1

Axel

Axle

Achse

Axe

32

1

Spännstift

Roll pin

Spannstift

Goupille de serrage

33

1

Skruv

Screw

Schraube

Vis

34

1

Bricka

Washer

Scheibe

Rondelle

35

1

Kamskiva

Cam

Kamscheibe

Disque à came

36

1

Handtag

Handle

Griff

Poignée

37

1

Fjäder

Spring

Feder

Ressort

38

1

Bricka

Washer

Scheibe

Rondelle

39

1

Skruv

Screw

Schraube

Vis

40

1

Spärr

Lock

Verriegelungsgriff

Poignée de verrouillage

41

1

Kuggsegment

Cog segment

Zahnsegment

Segment denté

42

1

Skruv

Screw

Schraube

Vis

43

2

Flänsmutter

Flange nut

Flanschmutter

Écrou à embase

44

1

Skruv

Screw

Schraube

Vis

45

2

Skruv

Screw

Schraube

Vis

46

1

Spännstift

Roll pin

Spannstift

Goupille de serrage

47

1

Ratt

Wheel

Handrad

Volant

48

2

Gavel underdel

Side, lower

Giebel, unten

Bâti partie inférieure

49

8

Bricka

Washer

Scheibe

Rondelle

50

8

Skruv

Screw

Schraube

Vis

51

1

Rörstag

Pipe strut

Rohrstrebe

Support tubulaire

52

1

Gavel utsvängbar sida

Side, openable side

Giebel, Nebentüren

Bâti côté pivotant

53

1

Motor

Motor

Motor

Moteur

54

2

Stag

Strut

Strebe

Support

55

1

Skruv

Screw

Schraube

Vis

56

1

Mutter

Nut

Mutter

Ecrou

57

1

Gavel transmissionssida

Side, transmission side

Giebel, Transmissionseite

Bâti côté de transmission

58

1

Axelsäkring

Axle lock

Achssperre

Arrêt d’axe

59

4

Mutter

Nut

Mutter

Ecrou

60

2

Skruv

Screw

Schraube

Vis

61

4

Skruv

Screw

Schraube

Vis

62

1

Fläns

Flange

Flansch

Bride

63

1

Fläns

Flange

Flansch

Bride

64

2

Klammer

Clip

Klammer

Crampon

65

2

Skruv

Screw

Schraube

Vis

Summary of Contents for 4135

Page 1: ...Bending Roll Machine 4135 Operating Instructions...

Page 2: ......

Page 16: ...Operating Instructions 4135 16 2013 05 23 SPARE PARTS...

Page 19: ......