4135 English, rev 3

5

operaTion

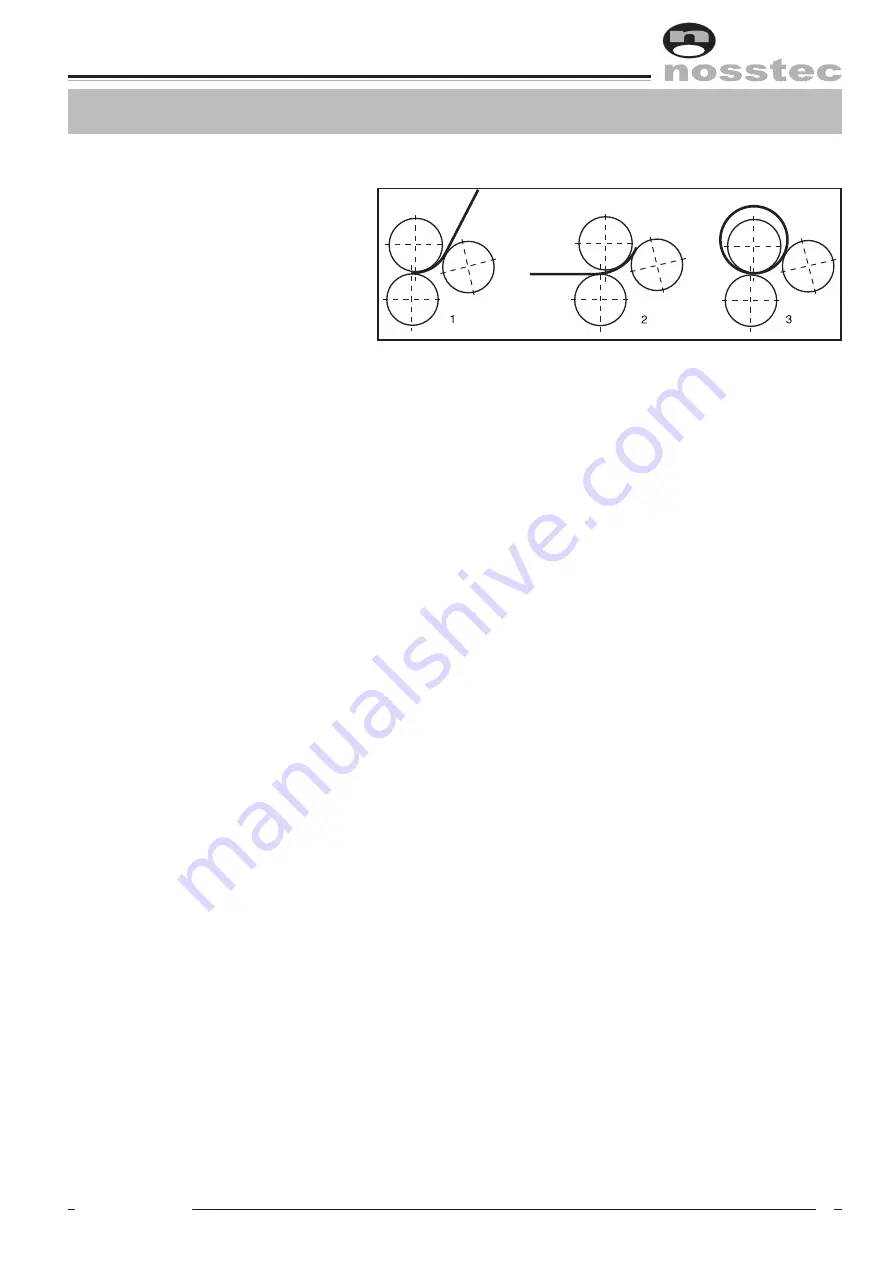

Prebending

In order to give the workpiece a

symmetrically round shape, it is

necessary to prebend the part of the

workpiece, which should be bent first.

This must be made from the back

of the machine and with the rolls

rotating in the opposite direction (see

picture 1 in the figure on the right).

Bending

Place the bending roll in the required position.

Introduce the prebent workpiece between the upper and lower rolls and use the bending roll as a back

gauge.

Turn the hand wheel of the lower roll so that the workpiece is clamped between the rolls. Bend the sheet

(check that the sheet runs above the bending roll as per figure above).

Adjust the bending roll and repeat the operation until the workpiece has got the desired shape. Swing

out the top roll and remove the workpiece. Swing back the top roll into its initial position.

At the maximum operating length and sheet thickness tubes down to 1.5x the diameter of the top roll

can be bent and for thinner material down to 1.2x the diameter of the roll.

When bending steel sheet or stainless steel the capacity of the machine will be reduced to about 2/3

compared to mild carbon steel sheet.

Cone (taper) bending

In order to facilitate cone bending the bending roll can be set diagonally as follows:

The bending roll can be set diagonally in both ends by loosening the screw of the cam disk and adjust

the handle upwards or downwards. When the desired inclination of the roll has been obtained, retighten

the screw of the cam disk

Note: Do not forget to reset the parallelism of the rolls after completed cone bending.

Summary of Contents for 4135

Page 1: ...Bending Roll Machine 4135 Operating Instructions...

Page 2: ......

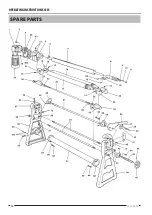

Page 16: ...Operating Instructions 4135 16 2013 05 23 SPARE PARTS...

Page 19: ......