8264 English, rev 3

5

operaTion

Prebending

In order to obtain a symmetrically round shape, it is necessary to prebend the front as well as the rear

edge of the workpiece. This prebending can be carried out by means of suitable equipment e.g. a

press brake or manual folding machine.

This operation can not be performed with a 8264 bending roll

machine.

Bending

This machine shall be used for bending sheets to a round shape. Also cylinders with conical shape can be

bent if the machine is equipped with cone bending device.

At the maximum operating length and the maximum sheet thickness tubes down to about 1,5 times the

diameter of the bending roll can be formed and for thinner sheets down to about 1,2 times the diameter

of the roll.

When bending steel sheet or stainless steel the maximum thickness capacity of the machine will be

reduced to about 2/3 compared to mild carbon steel sheet.

Bending operation:

The bending roll is screwed up so that the workpiece can be introduced between the bending roll

and lower rolls. After having cen tered the workpiece in the machine, the bending roll is screwed down

towards the workpiece so that a bend appears. How much the bending roll must be screwed down

depends partly on the thickness of the material and partly on the final diameter.

Generally the sheet must be run through the machine several times in order to obtain the desired shape.

When the work piece has been introduced between the rolls, the machine can be started by means

of the pedal switch. The workpiece should then be run through the machine until it nearly leaves the

lower roll. After this the bending roll is screwed down somewhat and the procedure is repeated but

in the opposite direction by means of the pedal switch. Continue to run the workpiece forwards and

backwards at the same time as the bending roll is screwed down, until the work piece has obtained the

desired shape.

In order to get a better cylinder, the workpiece can be run through the machine some extra times, either

direct after the rolling or after the joint has been welded and emery ground.

Summary of Contents for 8264

Page 1: ...Bending Roll Machine 8264 Operating Instructions...

Page 2: ......

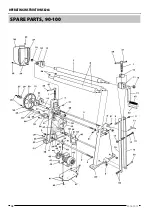

Page 17: ...8264 English rev 3 17 Spare parts 80 90...

Page 18: ...Operating Instructions 8264 18 2018 09 12 Spare parts 90 100...

Page 19: ...8264 English rev 3 19 Spare parts 100 110...

Page 20: ...Operating Instructions 8264 20 2018 09 12 Spare parts 120 130...

Page 23: ......