8264 English, rev 3

7

safeTy

General

This bending roll machine is designed with a view to eliminating personal injuries provided that the in-

structions in this manual are being followed.

Only authorized and trained staff is allowed to use the machine. Read the whole instruction manual and

make sure that you understand the contents before the machine is taken into use. It is important that

you read the safety instructions below.

Safety instructions in connection with the installation

The machine must be bolted to the floor with 4 pcs expansion shell bolts diameter 16 mm.

Electrical installation of the machine must be carried out by authorized staff.

Lifting instructions

This machine must be lifted by truck as long as it is packed

in a crate or a wooden case. When lifting it from the pack-

ing to the permanent working site an approved lifting de-

vice type travelling crane must be used. Instructions for lift-

ing be means of travelling crane:

1. Check that the top roll is in the locked position.

2. Set lower and bending roll in upper position.

3. Put a lifting sling around the rolls as per figure.

4. Lift carefully at the same time as you check that the

rolls are pressed together.

Regarding weights: see technical data

Dangerous area

The dangerous area of the machine is

described in the figure.

This area shall in an appropriate way be

marked in the floor.

A person staying in the dangerous area

will henceforth be called “exposed per-

son” and the user of the machine the

“operator”.

Operator,

prebending

Operator

1,5 m

1,5 m

1,5 m

1,5 m

Summary of Contents for 8264

Page 1: ...Bending Roll Machine 8264 Operating Instructions...

Page 2: ......

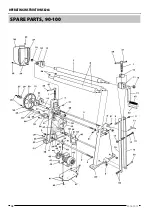

Page 17: ...8264 English rev 3 17 Spare parts 80 90...

Page 18: ...Operating Instructions 8264 18 2018 09 12 Spare parts 90 100...

Page 19: ...8264 English rev 3 19 Spare parts 100 110...

Page 20: ...Operating Instructions 8264 20 2018 09 12 Spare parts 120 130...

Page 23: ......