27

Instructions for the installer

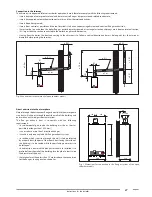

Connection to the chimney

The chimney is indispensable for correct boiler operation; it must therefore comply with the following requirements:

• it must be made of waterproof material and be resistant to flue gas temperature and related condensate;

• it must have appropriate mechanical characteristics and low thermal conductivity;

• it must be perfectly sealed;

• it must be as vertical as possible and the roof terminal is to have a cap ensuring efficient and constant flue gas exhaustion;

• it must not be less wide than the boiler flue gas outlet diameter; squared or rectangular section chimneys must bear an internal section,

10% larger than the section connected to the boiler draught excluder device;

• starting from the boiler, the duct connecting to the chimney is to follow a vertical direction and must be long not less than twice its

diameter before joining the chimney.

≥ 1,5 m

Ø

Ø

2

Ø

2

Ø

≤ 1 m

≤ 1 m

≥

3 %

≥

3 %

≥ 1,5 m

> 3

Ø

> 3

Ø

≥ 2 Ø

≥ 2 Ø

Fig. 6 Connections to the chimney of open chamber models

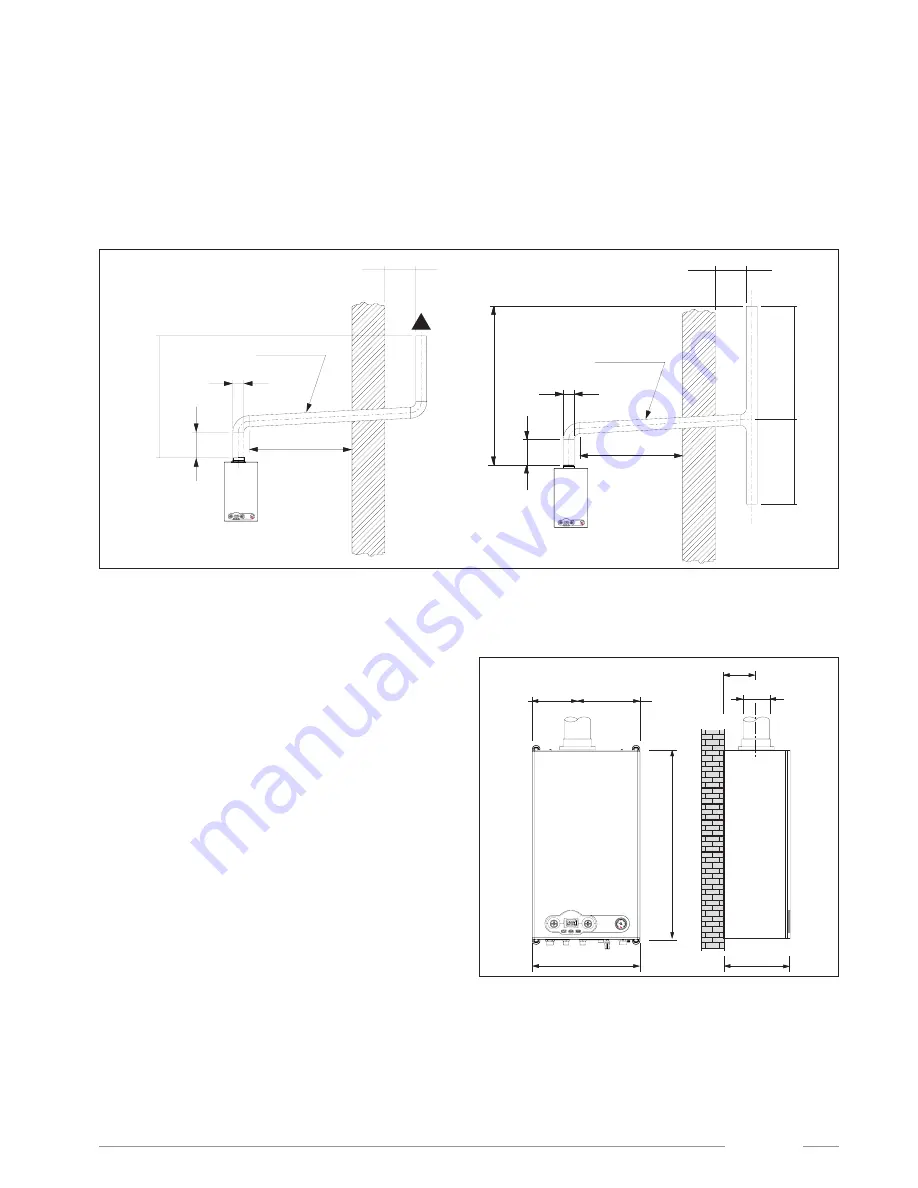

Direct emission into the atmosphere

Natural draught boilers can vent flue gas directly into the atmosphere

via a duct which goes through the outside walls of the building and

ends with an anti-wind gust device terminal.

The flue gas exhaust duct is to comply with the following

requirements:

• its sub-horizontal part inside the building must be as short as

possible (not longer than 1,000 mm);

• it is not to have more than 2 direction changes;

• it can host only one single boiler flue gas exhaust system;

• its section, which is passing through the wall is to be protected

by a sheath duct; the part of the sheath duct facing the inside of

the building is to be sealed, while the part facing outwards is to

be left open;

• its end section, on which the draught terminal is to installed, is to

protrude from the wall of the building for a length of a least twice

the diameter of the duct;

• the terminal must be no less than 1.5 meters above the connection

for the flue gas venting duct on the boiler.

400

700

250

Ø 130,8

118

168

232

Fig. 7 Dimensions for connection to the flue gas system of the open

chamber models

Summary of Contents for DELFIS Monothermal

Page 46: ...46...