Summary of Contents for Taurus Dual 100

Page 28: ...28 8 DECLARATION OF CONFORMITY...

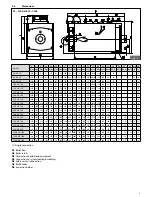

Page 29: ...29...

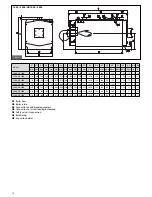

Page 30: ...30...

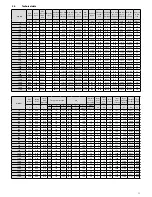

Page 31: ...31...

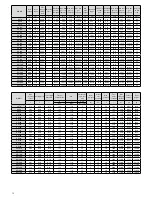

Page 32: ...32 ASSEMBLY INSTRUCTIONS FOR THE BOILER CONTROL PANEL...

Page 36: ...36 fig 26 Support centring openings for other models fig 27 Openings for self drilling screws...