26

The temperature gap between flow and return must not exceed 15°C in order to avoid thermal shocks to the boiler

structure.

The return temperature must not exceed 55°C so as to protect the boiler from corrosion due to condensation of flue

gases on surfaces which are too cold.

For this reason, it is advisable to moderate the return temperature by installing a 3 or 4-way mixer value.

The guarantee does not cover damage caused by condensate.

It is obligatory to install a recirculation pump (anti-condensate pump) to mix cold returns.

The pump must have a minimum capacity of about 5 m3/h and be at least equal to approx. 1/3 of the CH pump

capacity.

The burner switch must always be on.

This way, the water temperature in the boiler will remain around the value set with the thermostat.

NOTE

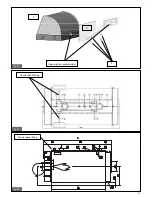

In the event of insufficient flue sealing in the front part (door and burner plate) or back part (flue chamber) of the boiler, it is

necessary to adjust the tension rods of the individual components. If this is not sufficient, replace the relevant gaskets.

NOTE

Do not open the door and do not remove the flue chamber while the burner is operating. Wait a few minutes after the burner

has been switched off to allow the insulations cool down.

7.

MAInTEnAnCE

Maintenance (and repair) operations must be performed only by qualified personnel who satisfy the requirements

established by the laws in force.

A correct maintenance of the boiler and burner in terms of procedures and time, ensures that these function under the best

conditions, with respect for the environment and in complete safety for persons, animals and property.

The manufacturer advises the Customer to contact the manufacturer’s Authorised Service Centres who are trained to perform the

required maintenance and repair operations.

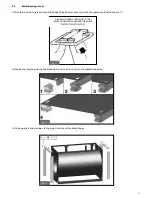

Before proceeding with maintenance, repair, component replacement or internal cleaning of the boiler, and in

particular, before opening the door of the furnace, it is necessary to take the following safety precautions:

- Interrupt fuel supply.

- If the boiler was operating, wait for it to cool down, allowing the water circulate within the system.

- Disconnect the boiler and burner from the mains.

- Place a sign on the boiler with the following text:

DO nOT UsE, MAInTEnAnCE In PrOgrEss, BOILEr nOn-OPErATIOnAL

Wear suitable clothing, gloves, goggles and face masks during maintenance operations.

Use a vacuum cleaner to remove the residue of combustion which must be disposed of in special containers showing the contents.

Combustion residues are highly polluting. Do not disperse into the environment but place them in the appropriate

collection areas.

7.1.

Ordinary maintenance

The operating conditions of the boiler vary from case to case and depend on: fuel used, burner regulation, number of times the

boiler is started up and system characteristics.

Therefore, it is not possible to establish in advance a set interval between one maintenance session and the next.

The service engineer must determine this time interval on the basis of an initial observation of the degree of soiling of the flue

system.

As a guide, the following intervals are recommended for cleaning the pipes (with the brush provided) and the agitators depending

on the type of fuel used:

• Once a year for gas boilers.

• Every three months for diesel-oil boilers.

• Once a month for naphta boilers.

Local regulations regarding maintenance must always be observed.

Summary of Contents for Taurus Dual 100

Page 28: ...28 8 DECLARATION OF CONFORMITY...

Page 29: ...29...

Page 30: ...30...

Page 31: ...31...

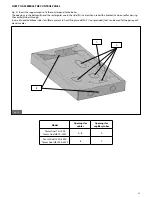

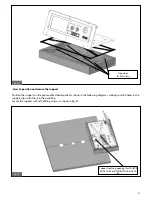

Page 32: ...32 ASSEMBLY INSTRUCTIONS FOR THE BOILER CONTROL PANEL...

Page 36: ...36 fig 26 Support centring openings for other models fig 27 Openings for self drilling screws...