C-Series IM 1 MAY 2014

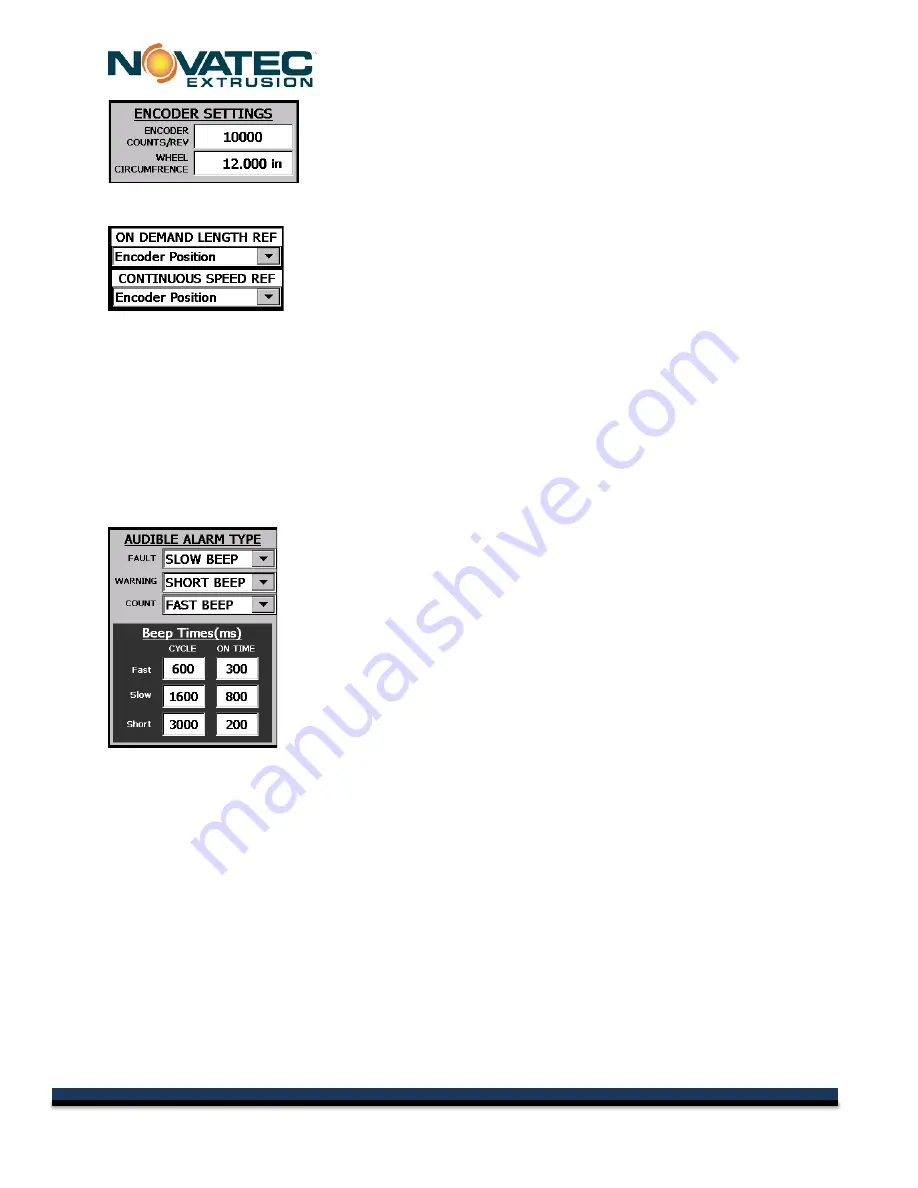

ENCODER SETTINGS

Encoder Counts/Rev

– The number of quadrature pulses per revolution

of the encoder. (If it is 2,500 ppr quadrature then the value is 10,000)

Wheel Circumference –

Distance for one revolution of the encoder,

typically the circumference around wheel connected to encoder. If the encoder is measuring

slightly off, change this value to correct.

ON DEMAND LENGTH REFERENCE

– Choose the measuring method

that the system will use to activate the cut sequence when using encoder

mode.

None

– The length is calculated based on the Estimated Line Speed

entered by the operator in the recipe. This is useful for setup or when the

customer wishes to enter the puller speed manually.

Encoder

– The encoder input pulses are used to determine the length.

ProfiNet

– An Ethernet connection between a Novatec supplied puller and the cutter is required.

The puller transmits its actual speed every 1/10 seconds and the cutter uses this to calculate the

accumulated length. It calculates the point between the 1/10 second data by assuming the last

received speed to get very accurate cuts.

CONTINUOUS SPEED REFERENCE

– This has the same options as the length reference but is

used to determine the speed reference when running in continuous. It is possible to use different

modes for each depending on how stable a signal is. The signals should be nearly identical or

unpredictable switching might occur when changing between On Demand and Continuous modes.

AUDIBLE ALARM TYPE

This is used to configure the horn sounds. Different sounds can be set for

Fault, Warning, and when the Count gets to set values. the choices are

None, Slow Beep, Short Beep, Fast Beep, and Continuous. Each beep

duration and cycle time can be customized so that operators can distinguish

between machines audibly.

31

© 2015 NOVATEC Inc. All Rights Reserved

Document: C-Series 7 MAY 2015