C-Series IM 1 MAY 2014

1

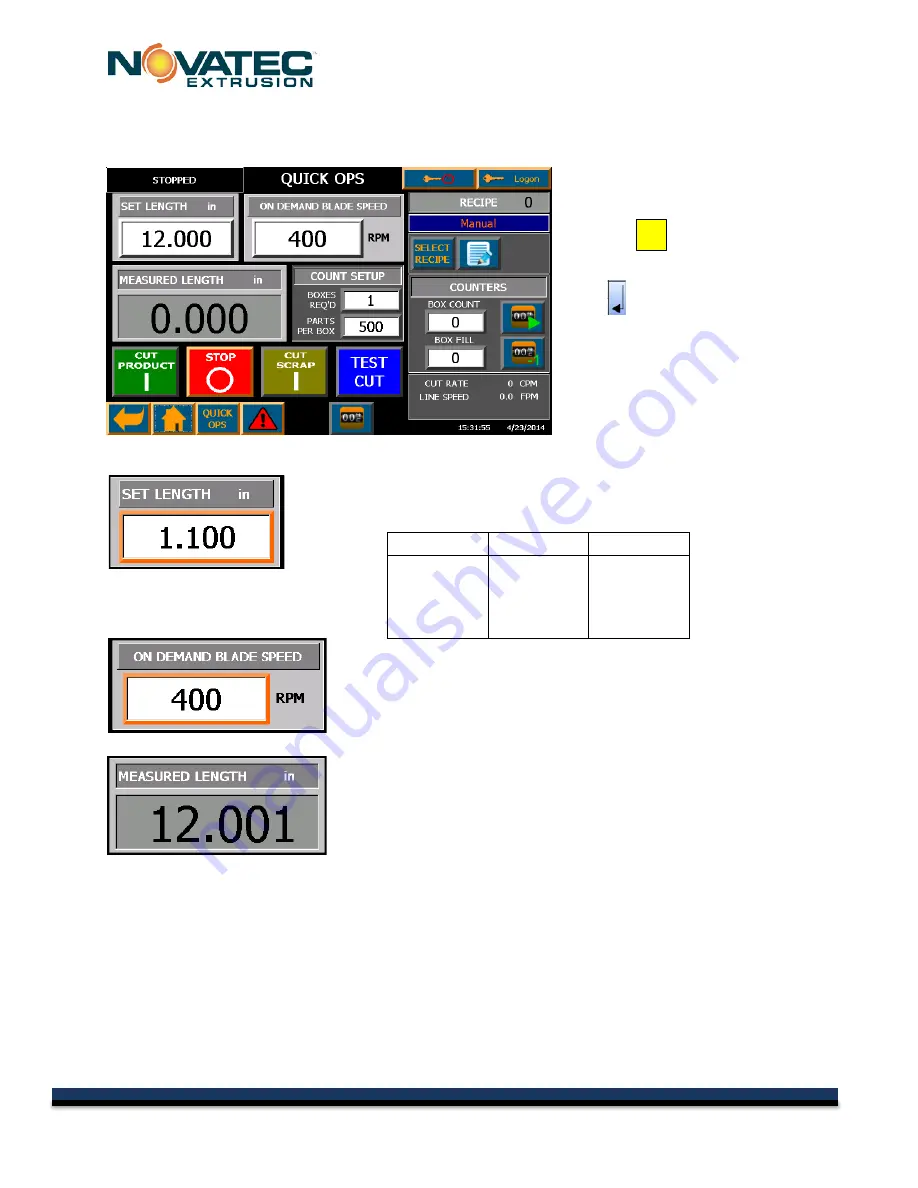

12.0 MACHINE OPERATION

The factory pre-sets allow the cutter to start production using the encoder input.

If you want to use the encoder input,

simply enter a length in the SET

LENGTH box. A numeric screen

will pop-up. Enter the cut length and

press to return to the Quick Ops

screen. Enter the RPM’s in the same

manner, based on your experience.

The cutter will run in ON DEMAND or

CONTINUOUS MODE based on your

entries.

12.1 Quick Ops Screen Items

Cut Parameter

- Used to enter the value to control when the cutter

activates. It is dependent on the cut mode set on the recipe screen. It will

always show the product cut values when the system is stopped.

Blade Speed -

Enter the optimum blade speed for the cut when

running in On Demand mode. In Continuous Mode, this is greyed out

and shows the currently running blade speed that is determined by

the calculation of Set Length and Line Speed.

Measured Length

- This is the length of the cut measured by the

encoder signal. If an encoder is not used, this field will always be

zero. It can be set up to always read the last cut length or hold the

last cut length for a specified time before showing the accumulated

cut length.

Cut Mode

Parameter

Units

Encoder

Set Length

in/mm

End

Sensor

Delay Time

sec

Time

Cycle Time

sec

1

19

© 2015 NOVATEC Inc. All Rights Reserved

Document: C-Series 7 MAY 2015