C-Series IM 1 MAY 2014

13.5 SETUP SCREEN 1

To change Time and/or

Date:

Press the appropriate

Button and enter the date as:

xx/xx/xxxx or the time as

xx:xx:xx (24 hour clock).

Press to return to the

SETUP 1 screen.

Press to access

User Configuration

to change the usernames, passwords and auto-

logoff times. See 13.3 on page 23. You can assign specific personnel or personnel levels for each of

the access levels.

All items on this page are accessible to be changes by a level 2 or higher user.

The arrow to go

to the second setup page will only appear for level 3 and higher users.

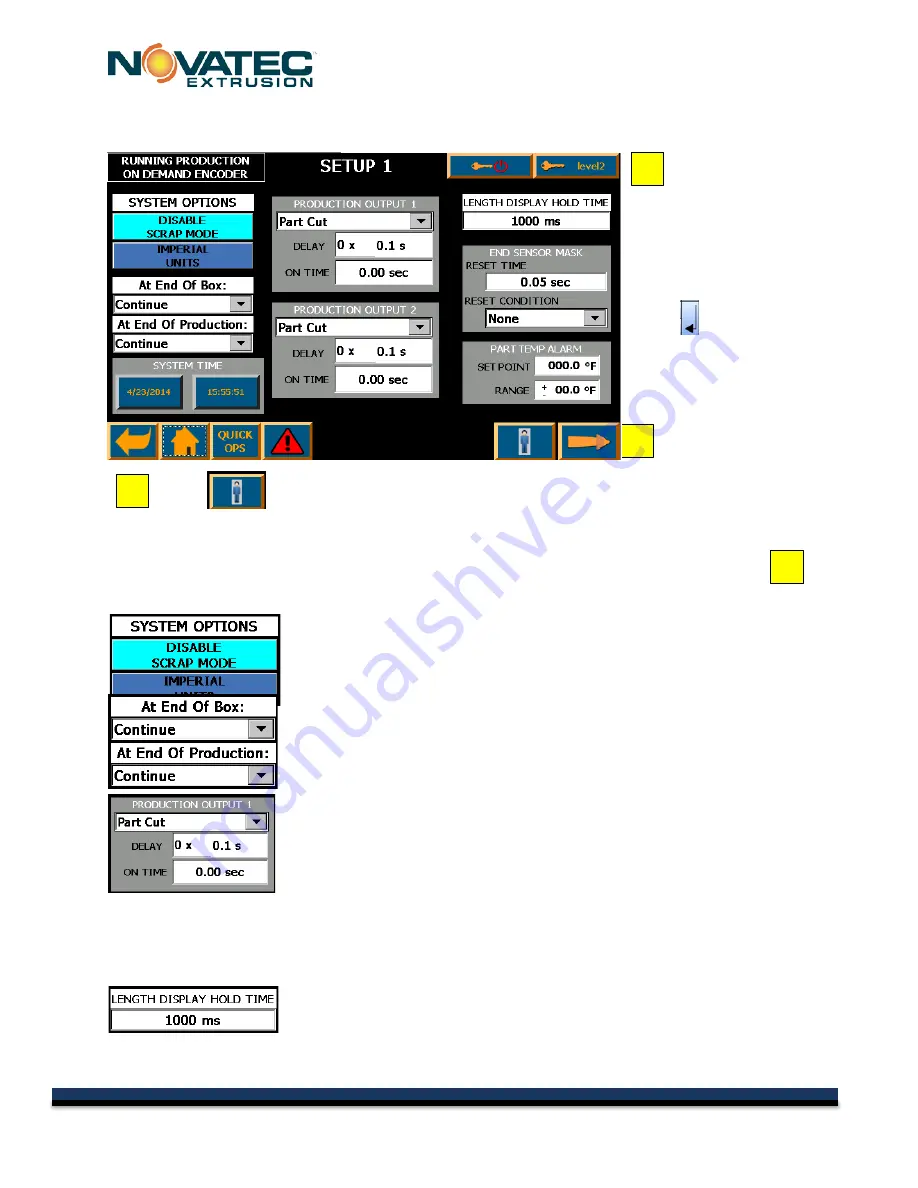

SYSTEM OPTIONS

Enable/Disable Scrap Mode

– Press this button to Enable Scrap Mode.

Imperial/Metric Units –

Press this button to toggle the display units

between English and Metric.

AT END OF BOX

Count Triggers -

Triggers change in machine operation when part count

reaches end of box and production. Is the same function as on the Counter

Screen.

PRODUCTION OUTPUTS 1 -

There are two dry contact outputs supplied in

the control panel. Q0.0 corresponds to Production Output 2 and Q0.1

corresponds to Production Output 1. They can be configured to trigger on

many events including Part Cut, Box Change, Production Done, Running,

Run Product, Run Scrap, Stopped or Faulted. The signal can be delayed

and held for a user settable amount of time. They are not high speed

response signals. There is a typical lag of about 30 ms with an error of +/-10 ms. If a higher speed,

more precise output is required, option NC8016 shown on schematics is required. Sales must be

contacted to ensure the proper form of the output device.

LENGTH DISPLAY HOLD TIME -

This value determines how long the

display will show the last cut length before showing the accumulated length

of the next part. Set it to zero to always show only the last cut length. It is

recommended to be set to at least 500ms. Parts that are cut faster than 500ms may be difficult to

see no matter the setting.

1

1

2

2

3

3

29

© 2015 NOVATEC Inc. All Rights Reserved

Document: C-Series 7 MAY 2015