C-Series IM 1 MAY 2014

END SENSOR MASK

It is commonly required to mask the end sensor signal after activation to

prevent subsequent activations. Set the timer value to prevent a second

activation until the time set has expired. Never set the value higher than

the time between cuts or cuts will be missed. The mask can be can also

be configured to reset on either the positive or negative going production

signals or by a customer provided signal to input 1.0 on the PLC.

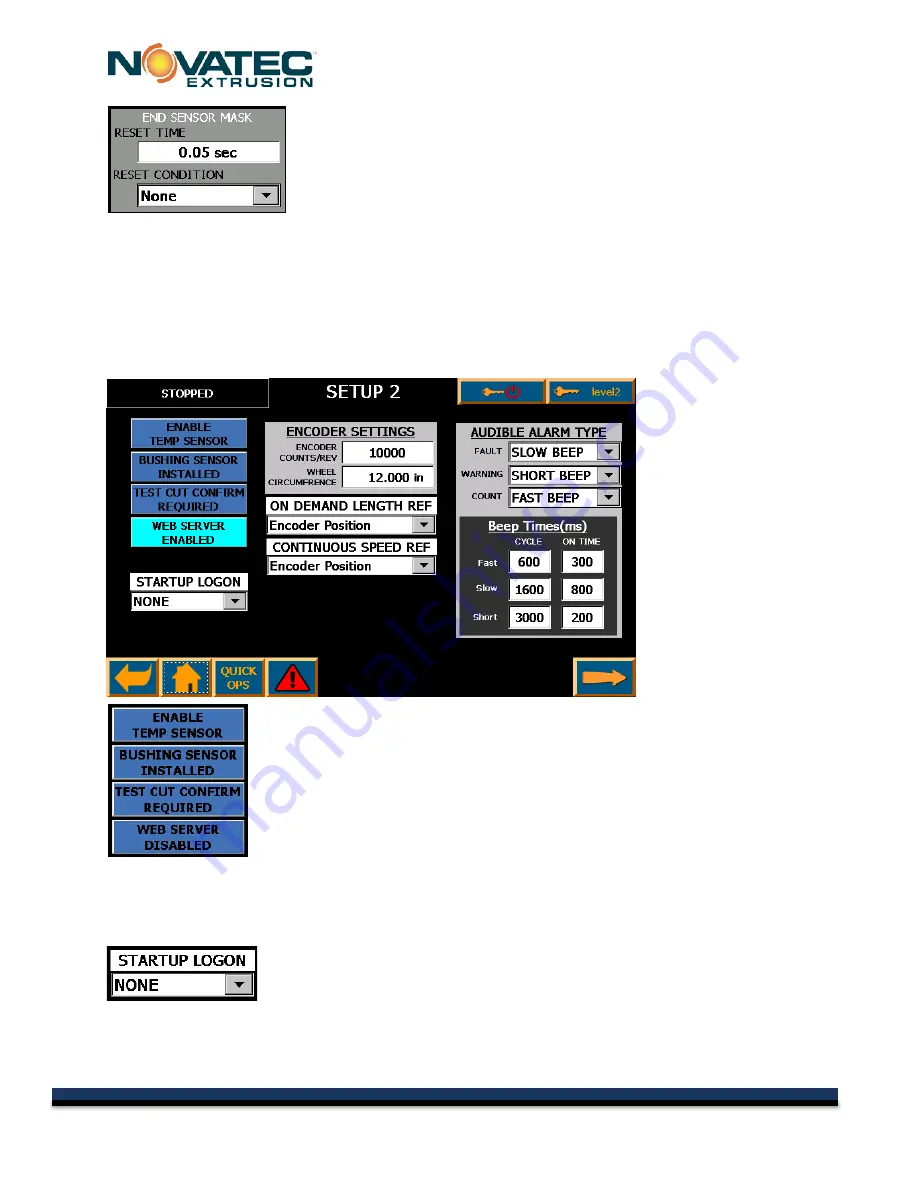

13.6 SETUP Screen 2

This screen is used to set some of the more advanced features of the equipment. All of the

items on the left column require a setup authorization. Everything else can be accessed by

level 3 authorization.

ENABLE TEMPERATURE SENSOR

–

This field enables the temperature

display on the Quick Ops Screen. This is an optional item that must be

purchased separately or the end user must install their own device.

BUSHING SENSOR INSTALLED –

Press this to enable bushing sensors if they

are installed. Sensors are not installed on systems that have permanently

installed bushings.

TEST CUT CONFIRM REQUIRED -

This button toggles the requirement for the

popup window to confirm a test cut. To avoid accidental activation, the test cut

button will require it be held for 1/2 second.

WEB SERVER ENABLED/DISABLED -

Toggles the availability of the screens to be accessed from

another HMI or web browser. If it is enabled without the required license installed, an annoying

message will appear every few minutes.

STARTUP LOGON

All machines ship with the user login set to none as default which means the

operator must log in to start the machine. The system can be set so that it is

always level 1, level 2 or level 3 when it starts or is logged off. Be careful when setting it to higher

levels because it may give unintended access to features which operators don't understand.

30

© 2015 NOVATEC Inc. All Rights Reserved

Document: C-Series 7 MAY 2015