SECTION I

INTRODUCTION

This operation and maintenance manual is furnished with each

NOVAIR 2000

. It outlines the general use

and maintenance requirements for efficient and safe operation.

READ ALL INSTRUCTIONS AND DATA IN THIS OPERATION AND MAINTENANCE MANUAL PRIOR

TO OPERATION OF THIS EQUIPMENT.

These instructions are for your protection and convenience. Please read them carefully. Failure to follow

these precautions could result in injury, death or damages. Whenever using electric powered equipment,

basic safety precautions should be followed.

If after reading this manual you still have questions, contact a

NOVATEK

authorized distributor or

NOVATEK

directly by dialing 1-866-563-7800.

SECTION II

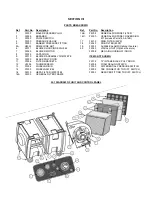

GENERAL DESCRIPTION

The

NOVAIR 2000

is a portable, electrically powered Air Filtration machine, designed and manufactured by

Novatek Corp. The machines function is to filter air and remove suspended airborne particulates.

This unit has a three stage filtering system. The Pre-Filter stage captures the bulk of the dust and debris.

The second stage utilizes a two-ply Ring Filter that captures any dust and dirt able to penetrate the

Pre-Filter. The final stage is the 99.97% - 0.3 micron HEPA Filter or the 5 micron general purpose filter. The

HEPA filter is utilized in abatement work or areas where an extremely high level of filtration is desired. The

general purpose filter is utilized when trying to reduce visible air born particulates that are deemed non

hazardous.

The

NOVAIR 2000

requires a 110/115V - 20 Amp, single phase power source.

WARNING

Do not use circuits exceeding specified voltage. Higher voltage will damage controls and could

cause shock or fire hazard.

SECTION III

ROUTINE MAINTENANCE

Inspect the unit for any loose or damaged parts prior to use.

CAUTION:

Be sure power supply is in the OFF position prior to inspection!

A. Clean the surfaces of the unit to remove accumulated dust or dirt. Do not use petroleum distillates,

solvents, or thinners as cleaning agents. Remove any accumulated dust and dirt from control panel.

B. Periodic checks should be made of the filter brackets to ensure thumbscrews and knobs are secure.

C. Filters should be checked daily and replaced if needed. This will help ensure proper air flow and extend

motor life.

D. Inspect ALL power connection. Be sure that the recessed plug is secure to the panel. If recessed plug

is not secured, electrical shock or shortage may occur.

E. Inspect your power cords connections for breaks, scorched areas, melting, oxidation, or signs of wear.

If cord shows ANY of these signs, replace.

CAUTION:

Do not tamper with or modify the blower housing, control panel, drive motor, or wiring

scheme. Tampering or modifications could result in premature wear or failure and will void factory

warranty.

Summary of Contents for novair 1000 f1000

Page 1: ......