F. Insert the female end of your power cord into the male recessed plug (diagram #20.1, item #1), and set

the power switch to the “High” position. If the reading on the pressure gauge exceeds 3.0-3.4” of water

column, the HEPA or General Purpose Filter should be inspected.

HEPA/GENERAL PURPOSE FILTER

A. Follow steps

A-D

listed above for Ring Filter replacement.

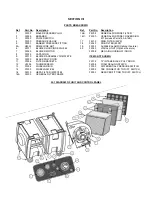

B. Locate the bracket thumbscrews (diagram #20.1, item #12). Loosen the four bracket thumbscrews by

turning them counter clockwise.

C. With all four thumbscrews loose, push the top of the filter brackets (diagram #20.1, item #11) inward

towards each other, and remove from the front of the unit.

D. Firmly grasp the right and left sides of the HEPA or General Purpose Filter (diagram #20.1, item #16),

and pull the filter directly towards you. Remove the used filter and dispose of accordingly

E. Carefully inspect the replacement HEPA/General Purpose Filter gaskets for cracks, gaps or defects.

Any defective gaskets must be replaced.

F. The HEPA and General Purpose Filters have two sides; one side has a gasket, the other does not.

Insert replacement HEPA or General Purpose Filter, gasket side first, into machine and press firmly

against

the housing’s internal rib.

G. Reinstall the filter brackets. Once the brackets are installed, turn the thumbscrews clockwise until tight.

This will secure the main filter.

H. Reinstall Ring Filter and Pre-Filter. (Reference Pre-Filter and Ring Filter Replacement).

I.

Reinsert the Black Filter Door.

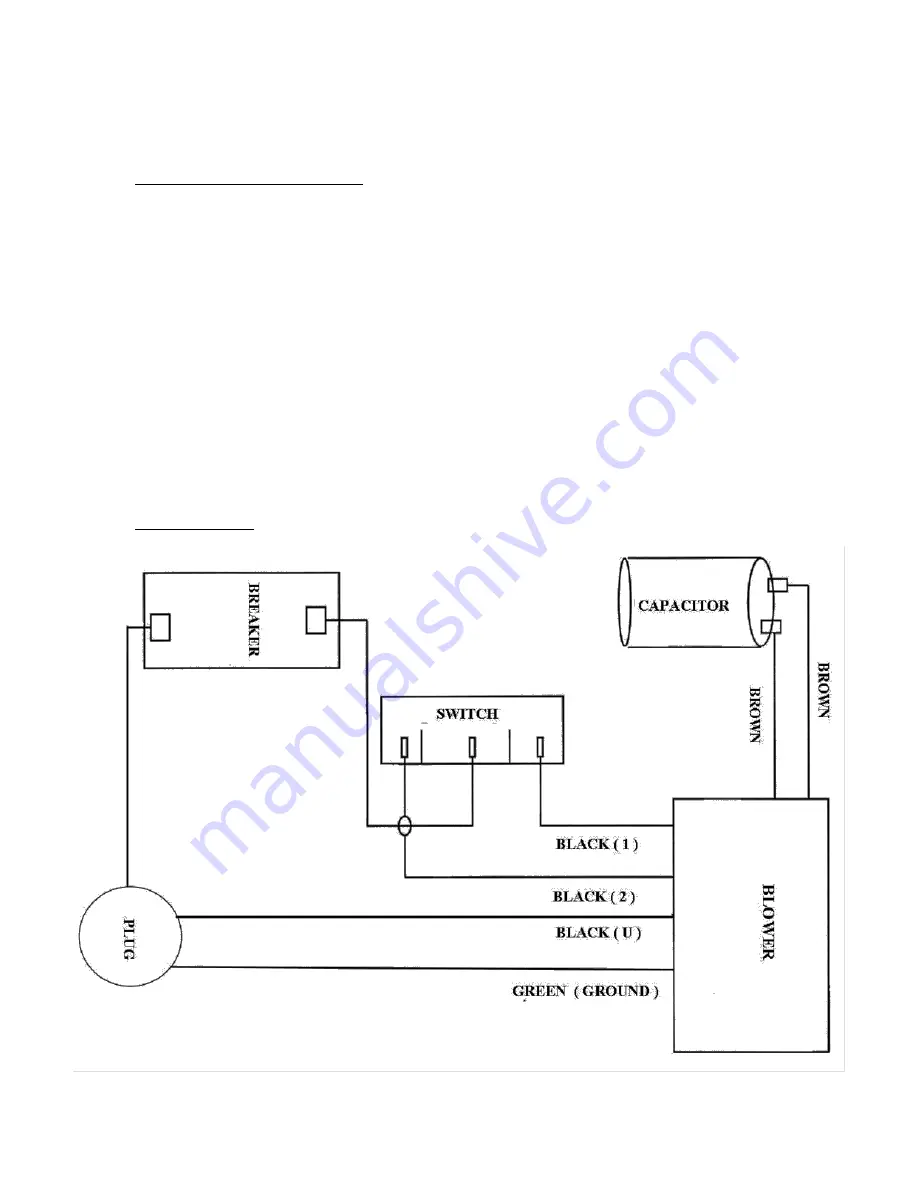

SECTION VI

WIRING DIAGRAM

Summary of Contents for novair 1000 f1000

Page 1: ......