45

PRODUCT GUARANTEE:

All products purchased by consumers, as defined in

Article 3 of the Consumer Code (Legislative Decree

no. 206 of 6 September 2005 and subsequent

amendments), are covered by the legal guarantee

of the seller under Article 128 and subsequent

amendments of the consumer Code. In case of lack

of conformity of the product, we invite the consumer

to contact their dealer within the statutory deadline.

WATER TREATMENT

• The hardness of the domestic water supply affects

the operation and the cleaning frequency of the

thermostatic mixer and boiler unit.

• In case of water with hardness above 15°f an antiscale

device is recommended. The choice of device should

be made according to the characteristics of the

water supply.

This symbol indicates important product

instructions or important safety information.

IMPORTANT:

Before you start to assemble and install the product,

carefully read through all the instructions. Unpack the

components and check that nothing is missing and

that there are no damaged or faulty components,

remove the transparent protective film. Before

you install the shower cubicle in its final position,

perform a test run. Run the unit for several minutes

and check for water leaks and any damage caused

during transport and handling. This product should

be installed by suitably skilled personnel.

N.B.: This product is designed for installation on

finished walls and floors.

Warranty claims must be produced with the purchase

invoice and the product assembling instructions.

The drawings and illustrations in this manual are

provided for information purposes only.

The manufacturer reserves the right to make changes

and improvements without prior notice.

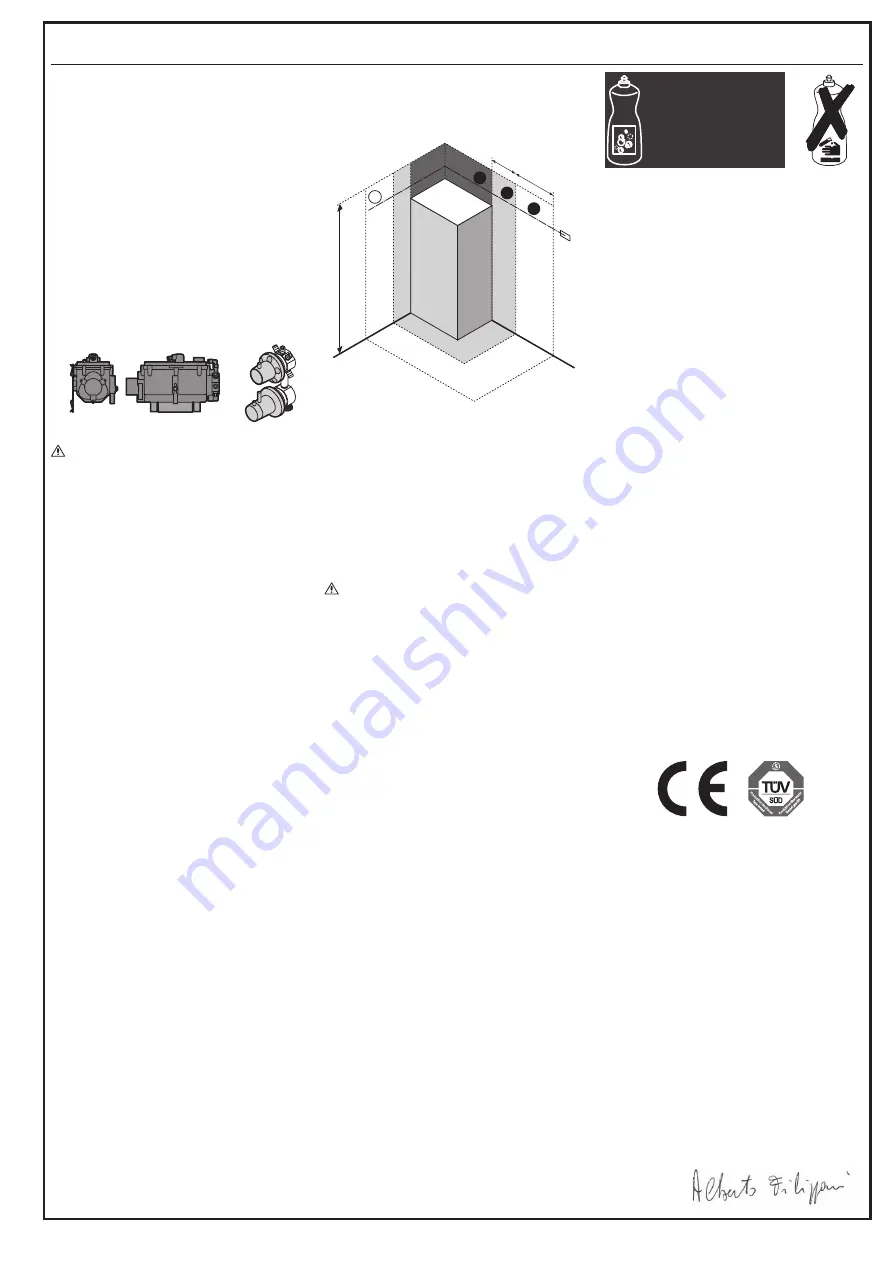

Electrical connection:

The manufacturer certifies that the product

conforms to current health and safety regulations

at the time of sale and that the product has the CE-

mark and Declaration of Conformity. All products

and components are tested during manufacture in

accordance with the relevant reference standards

and company quality system procedures. In order

to ensure that your manufacturer product maintains

these high standards after installation and throughout

its service life, please read the following instructions.

1) Check that the mains electrical equipment

connected to cubicle conforms to current electrical

standards and regulations and is fitted with a fully

efficient earth connection.

2) Current electrical regulations forbid the installation

of any electrical equipment (e.g. plugs, switches)

inside a radius of 60 cm from the cubicle and at a

height of 225 cm.

3) Check that rating of the mains power supply line

matches the absorbed power specified for the

cubicle (see Technical specifications).

4) The electrical connection between the cubicle and

the mains must be protected against water spray

and must have a protection rating of IP55 or higher.

5)

The electrical equipment upstream from the

cubicle must be fitted with an omnipolare 30 mA

switched circuit breaker with a minimum contact

opening of 3 mm, which conforms to current

electrical regulations.

6) The manufacturer declines all responsibility for

injury or damage resulting from failure to observe

these instructions..

(I)

~

2250

1

2

3

600 mm

2400 mm

Dismantling the shower valves:

In the event of the formation of lime scale and a

resulting malfunctioning of the shower valves,

dismantle the parts (fig. A/B/C...). We recommend you

immerse the cartridge in normal vinegar until it is

completely lime scale-free.

To ensure correct operation of the thermostatic mixer,

the unit must be supplied from a boiler or a water

heater providing 6 to 7 litres per minute of water at a

temperature of 60/65°C.

INSTRUCTIONS FOR USE:

electrocution Hazard. Do not use electrical

equipment of any type inside the shower

enclosure when the shower is operating.

PRECAUTIONS:

Integrated cubicles will provide a variety of benefits

if used properly. You should observe the following

precautions.

1) Do not exceed a maximum water temperature of

45°C.

2) Do not use the shower or the steam bath after a

heavy meal and while you are still digesting.

3) Do not exceed the maximum load of the seat (120

kg).

4) Children and the infirm should only use the cubicle

under the supervision of an adult.

5) Do not use the steam bath for longer than 20 to 30

minutes. Maximum permitted steam bath times

vary with age and body weight.

6) Persons with serious heart problems, high blood

pressure and acute illnesses should consult a

medical practitioner before using the steam bath.

7) SCALDING HAZARD. During a steam bath, keep

your feet away from the steam outlet nozzle.

CLEANING THE SHOWER UNIT:

CARING FOR YOUR CUBICLE

The cubicle panels are made with acrylic parts and

must be cleaned using a liquid detergent and a soft

cloth or sponge. Use a good quality household liquid

detergent. To prevent scale deposits, wipe dry using a

chammy leather or a soft lint-free cloth that removes

stubborn deposits without leaving traces. Limescale

deposits may be removed using specific detergent

products. To restore shine to the acrylic surface polish

with an ordinary wax polish such as car wax. DO NOT

USE ABRASIVE CLEANERS, ALCOHOL OR ALCOHOL

BASED PRODUCTS, ACETONE OR OTHER SOLVENTS.

Liquid soap

TROUBLESHOOTING:

Before calling the Service Centre, check that:

• The hoses are properly connected and not kinked.

• Hot and cold water is being correctly delivered to

the wall fittings.

• The water supply system was bled before the shower

unit was installed.

• The mains power supply is reaching the steam

generator and the green Power On LED on the

control panel is lit.

WASTE DISPOSAL:

For the disposal of the product or its parts, follow

the local regulations on matters of waste disposal.

For Italy, Legislative Decree n. 152 of April 3, 2006

will hold, and for the other EU countries, Directive

2008/98/EC.

EC DECLARATION OF CONFORMITY:

The manufacturer Opus Engineering S.r.l. via Mantova,

1023, 46030 Borgo Virgilio (MN) Italy declares under

its responsibility that the cubicle fitted with steam

generator mod. S 300 conforms with the following

European directives EEC 2006/99, EEC 2004/108

as amended EEC 92/31, EEC 93/68 and with the

following European standards:

EN62233

EN55014-1

EN55014-2

EN60335-1

EN60335-2-15

EN61000-3-2

EN61000-3-3

EN61000-4-2

EN61000-4-3

EN61000-4-4

EN61000-4-5

EN61000-4-6

EN61000-4-11

ENGLISH

Romanore di Borgo Virgilio, lì 31.10.2008

Opus Engineering S.r.l.

Alberto Filipponi

Amministratore delegato

Summary of Contents for 2P 120x80 base dx p.150

Page 13: ...13 9 8 ø8 mm S8 5x40 6 5x24x2 x2 3 5x9 5 ...

Page 14: ...14 11 10 M5x16 ...

Page 15: ...15 No OK 12 13 3 5x32 3 5x32 x2 ...

Page 16: ...16 14 3 5x25 ø3 A 2P 120 pag 17 C GF90 pag 27 B R90 pag 22 ...

Page 17: ...17 2P 120x80 A1 A 3 5x45 ...

Page 18: ...18 A2 A3 3 5x45 ...

Page 19: ...19 150 mm 150 mm A4 A5 150 mm 150 mm ø 3 3 5x9 5 ...

Page 20: ...20 A6 A7 h 1884 mm h 1883 mm h 1900 mm h 1883 h 1900 ...

Page 21: ...21 A8 No OK x6 ø3 3 5x9 5 ...

Page 22: ...22 R 90 B1 B No OK x3 ø3 3 5x9 5 ...

Page 23: ...23 B2 B3 No OK x3 ø3 3 5x9 5 M4x10 n 4 ...

Page 24: ...24 B4 B5 a b a a b x2 x2 1 2 2 OK No b ...

Page 25: ...25 B6 B7 ...

Page 26: ...26 B8 110 mm 110 mm ø 3 3 5x32 ...

Page 27: ...27 GF 90 C1 C ...

Page 28: ...28 C2 C3 150 mm 150 mm 150 mm 150 mm ...

Page 29: ...29 No OK x6 ø3 3 5x9 5 C4 C5 ...

Page 30: ...30 C6 ...

Page 31: ...31 x2 15 16 ø3 mm R 90 2P 120 GF 90 3 5x25 mm n 2 4 3x9x1 n 2 ...

Page 32: ...32 17 18 M4 4x16x1 M4x20 ...

Page 33: ...33 19 20 3 5x19 n 2 3 5x9 5 n 2 No OK ø3 ø3 A A x2 A A B B B ...

Page 36: ...36 24 25 A B C 2 1 M5x50 M5x70 ...

Page 37: ...37 26 27 x2 ...

Page 39: ...39 No No H2O H H H H H2O F G H I ...

Page 40: ...40 38 C OK 38 C No 38 C OK J K1 K2 A B 38 C 38 C ...

Page 41: ...41 38 C OK 38 C No L M K3 A B 38 C ...

Page 55: ...55 Note ...

Page 56: ...60530IST_08 05 2016 ...