Operating Manual

LA-BO

Start signal

ALX 92x:

► Connect the start signal to the product sensor input of the AI interface.

For details see service manual ALX 92x, topic section “Applicator Interface”, chapter “Pin assign-

ments”> “Product sensor connection”.

ALS/XLS 2xx, ALS 306 or ALX 73x:

► Connect the start signal to the M12-connector “Start”.

(ALS/XLS 2xx, ALS 306) For details see service manual ALS/XLS 2xx or ALS 306, chapter “Electron-

ics Description”> “Applicator Interface”> “Pin assignment for product sensor connection”.

(ALX 73x) For details see service manual ALX 73x, topic section “Dispenser Electronics”, chapter “Ap-

plicator Interface”> “Pin assignment for product sensor connection”.

XPA 93x

:

► Connect the start signal to the M12 connector “Start” (BasicIO board, leftmost).

For details see service manual XPA 93x, chapter “Electronics Description” > “Boards” > “BasicIO” >

“Connection A”.

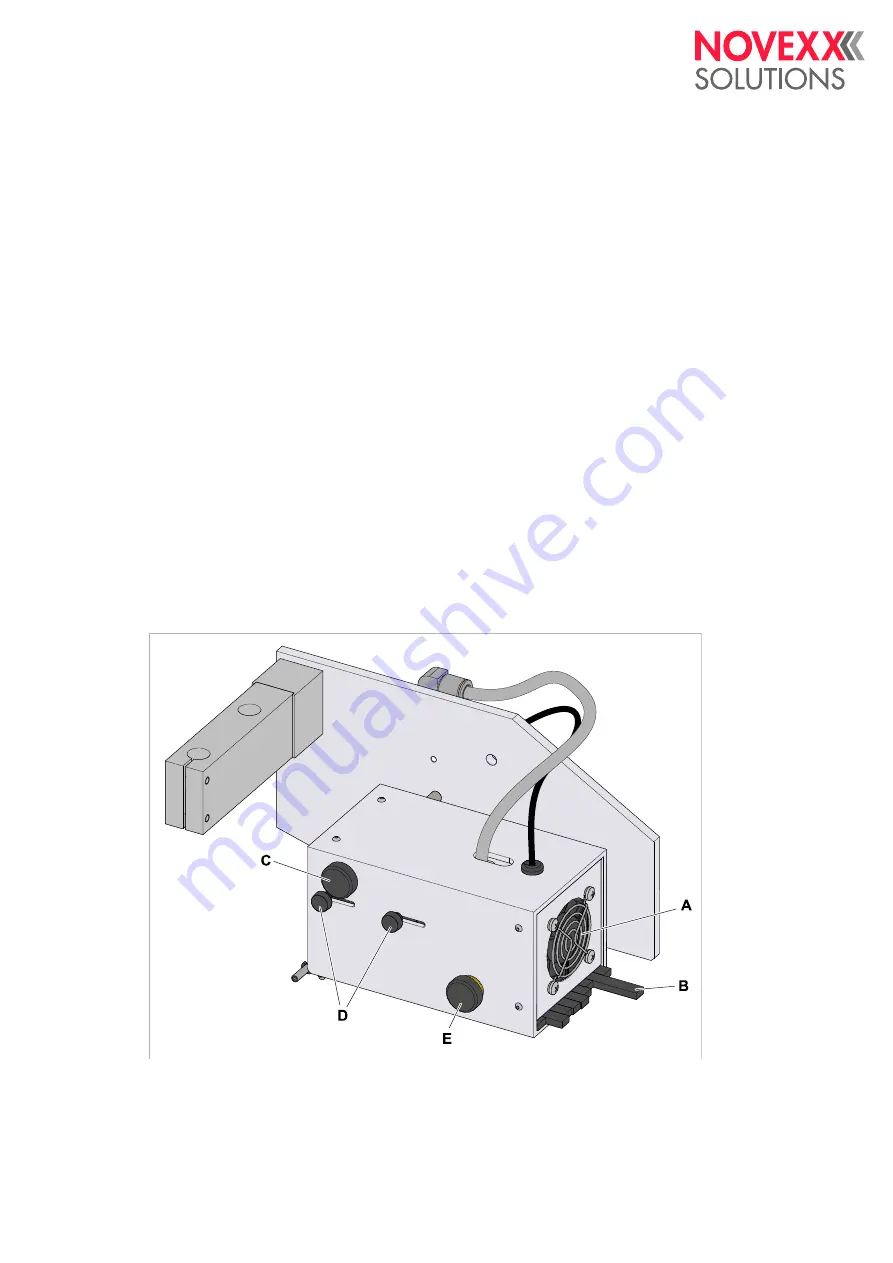

COMPONENT OVERVIEW

Front side

Fig. 1: Control elements on the front side of the LA-BO (here: version for ALS/XLS 2xx, ALS 306 and ALX 73x).

Edition 05 - 08/2022

11

Product description

Component overview