26 - EN

These assembly, operation and maintenance instructions must be kept for the entire period of use!

2.3

Personnel qualifications

The following persons are authorized to carry out the

installation and maintenance:

•

Skilled workers with relevant training, e.g.

industrial mechanic

A skilled worker is a person who, due to his/her pro-

fessional training, his knowledge and experience as

well as due to his/her knowledge of the relevant regu-

lations, is able to judge the work assigned to him/her

as well as to identify possible hazards.

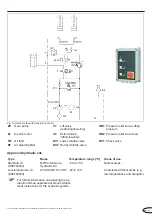

The following persons are qualified to perform elec-

trical installation work and to work on the electrical

system:

•

Qualified electricians

Skilled electricians must be able to read and under-

stand electric circuit diagrams, to put electrical sys-

tems into service and to maintain them, to wire con-

trol cabinets, to install the control software, to ensure

the functionality of electrical components and to

identify possible hazards resulting from handling elec-

trical and electronic systems.

The following persons are qualified to work on the hy-

draulic system:

•

hydraulics specialists

Skilled hydraulics specialists must be able to read

and understand hydraulic circuit diagrams, to put hy-

draulic systems into service and to maintain them, to

interconnect hydraulic components, to adjust flow and

pressure limiters, to ensure the functionality of hy-

draulic components and to identify possible hazards

resulting from handling hydraulic systems.

The following persons are authorised to handle the

product:

•

Operating personnel

The operator must have read and understood the in-

structions, in particular the "Safety" chapter and must

be aware of the hazards associated with handling the

product and the controlled dock leveller.

The operator must have been instructed with regard

to handling the controlled dock leveller.

The following persons are authorised to carry out as-

sessments and installations of dock levellers:

•

Qualified person according to EN 1398:2009

Person who, by way of training and experience, has

sufficient knowledge in the field of dock levellers and

who is sufficiently familiar with relevant rules and reg-

ulations to be able to assess the safe condition of

dock levellers.

2.4

Potential hazards associated with the

product

The product has undergone a risk assessment. The

product's design and construction, which are based

on this risk assessment, correspond to the current

state-of-the-art. The product is safe to operate when

used as intended. Nevertheless, residual risks re-

main.

WARNING

Hazardous voltage!

Fatal electric shock when touching live

parts. Observe the following safety rules

when working on the electrical system:

•

Disconnect from the mains.

•

Secure against inadvertent switch-

on.

•

Verify de-energised state.

•

Work on the electrical system may

only be performed by skilled electri-

cians or instructed persons working

under the direction and supervision

of a skilled electrician in accordance

with the electrotechnical rules and

directives.

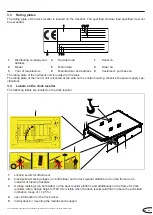

WARNING

Crush hazard by moving dock

leveller!

Limb crush hazard by moving dock lev-

eller.

•

Always mount external command

transmitters within sight of the dock

leveller.

•

The dock leveller must be visible

from the place of operation.

•

The optional control panel must be

equipped with an emergency stop

switch.

CAUTION

Tripping or falling hazard when

loading!

With the control switched off, triggered

emergency stop switch or active restart

lock, the floating position of the dock

leveller is not active and the vertical

movements of the truck are not bal-

anced out.

•

It is not permitted to drive on the

dock leveller until restart.

Summary of Contents for NovoDock L530

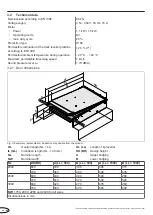

Page 139: ...A3 c 4 x...

Page 141: ...A5 c 4 x 181 250 mm DZ2 100 180 mm DZ1...

Page 150: ......

Page 151: ......

Page 152: ...docking Solution und Service GmbH Springrad 4 30419 Hannover Germany DS0805301 05 2022...