EN - 27

These assembly, operation and maintenance instructions must be kept for the entire period of use!

3

Product description

3.1

General product overview

9

10

11

12

2

4

1

5

7

6

8

3

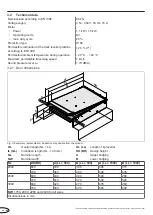

Fig. 1:

Exemplary representation, illustration may deviate from the product

1

Control unit

5

Lip leveller cylinder

9

Side panel/protective panel

2

Underride area

6

Hydraulic unit

10

Lifting cylinder

3

Cabling

7

Loading bridge platform

11

Warning stripes

4

Lip leveller

8

Rating plate

12

Frame

The loading bridge platform is hinged on the side of

the loading ramp and can therefore be adjusted in

height on the side of the vehicle. The lip leveller is

used for placing the platform on the truck loading

area. The hinged lip controls the height compensation

even if the truck is moving in height. At the same

time, it allows the truck to be driven over with a forklift

truck.

The loading bridge platform is aligned flush with the

ground and can be driven over with full nominal load

when it is in resting position.

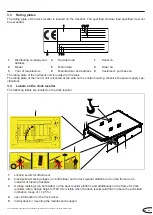

Option: Retracting flaps on the sides on the

lip leveller

The lip leveller of the loading bridge may be equipped

with retracting flaps on the side that are moved back-

wards independently of the central part (i.e. automat-

ically in the case of resistance or manually sliding).

This reduces the width of the contact surface so that

trucks with narrow loading areas can also be

handled. When the loading bridge moves back to its

resting position, the retracting flaps at the sides are

automatically moved back to the initial position. This

means that the full width of the lip leveller is available

again the next time it is extended.

Fig. 2:

Exemplary representation, illustration may deviate from the

product

Summary of Contents for NovoDock L530

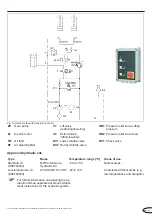

Page 139: ...A3 c 4 x...

Page 141: ...A5 c 4 x 181 250 mm DZ2 100 180 mm DZ1...

Page 150: ......

Page 151: ......

Page 152: ...docking Solution und Service GmbH Springrad 4 30419 Hannover Germany DS0805301 05 2022...