34 - EN

These assembly, operation and maintenance instructions must be kept for the entire period of use!

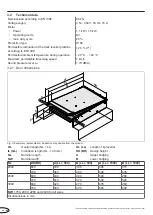

4.5.4 Installation condition EZ

NOTICE

Malfunction due to damaged cables

•

Do not crush the cables of the con-

trol unit located on the outside of

the dock leveller!

, page A7. Insert the loading bridge into the

installation point in a way that the weld-on attach-

ments are positioned in the reinforcement. Ensure

that the dock leveller is not braced and that a lateral

clearance of 10 mm (+0/-2 mm) between frame and

dock leveller platform is maintained.

, page A7. Align the dock leveller horizont-

ally. Make sure that the diagonal dimensions of the

loading bridge do not deviate by more than 2 mm.

, page A8. Fix the frame of the loading

bridge to the substrate with suitable screws. Connect

the loading bridge to the reinforcement using welding

points.

Remove the transport locks on the dock leveller plat-

form.

4.6

Further assembly steps

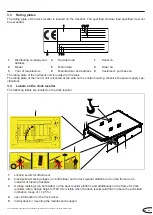

4.6.1 Removing the transport lock of the lip

leveller

, page A8. Disassemble the transport lugs.

For dock levellers with a lip leveller length of 500 mm,

remove the screws and retaining plates on both sides

on the lip leveller.

4.6.2 Test run

, page A9. Insert the CEE plug of the control

unit into a socket. Carry out a test run of the dock lev-

eller (see assembly and operating instructions of the

control unit). In doing so, check all functions of the

dock leveller.

4.6.3 Inserting the maintenance support

, page A9. Move the dock leveller to its up-

permost position. Switch off the main switch and se-

cure it against switch-on.

Insert the maintenance support first at the top and

then at the bottom into the receptacle on the dock

leveller.

Switch on the main switch. Lower the dock leveller.

Switch off the main switch and secure it against

switch-on.

4.6.4 Checking the hose connections

Check the hose connections on the three hydraulic

cylinders and on the hydraulic unit for tightness.

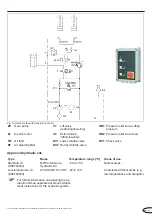

4.6.5 Connection to the control unit

, page A10. Disconnect the cables of the hy-

draulic motor at the control unit (see assembly and

operating instructions of the control unit).

Assemble the control unit at the intended installation

point.

Guide the cables through the empty conduit to the

control unit and reconnect them to the control unit.

Fix the cable under the dock leveller platform with the

supplied cable clamps.

4.6.6 Mounting the cable channel

, page A10. Use a cable channel (not in-

cluded in the scope of delivery) to protect the cables

between the outlet on the floor and the control unit.

4.7

Completion

4.7.1 Installation condition CZ

, page A11. Weld the weld-on attachments of

the loading bridge to the pegs.

If the dock leveller is galvanised, spray the area

around the weld seams with cold galvanising spray

(not included in the scope of delivery) and allow to

dry for at least 30 minutes.

Touch up all damaged areas in the paint with the sup-

plied touch-up paint.

, page A11. Seal the slots between the load-

ing bridge frame and the building before pouring in

the concrete grout. We recommend that you cover

the loading bridge platform with a protection film be-

fore pouring in the concrete grout.

Pour in the concrete grout. Make sure to use con-

crete of appropriate quality, at least C20/25. If you

pour in the concrete grout from a great height, make

sure that the lateral pressure does not become too

high during the pouring and compaction process.

Otherwise, the side walls may deform.

Close the holes in the loading bridge platform with the

plastic plugs.

4.7.2 Installation condition DZ1 and DZ2

, page A12. Weld all weld-on attachments of

the loading bridge to the pegs.

If the dock leveller is galvanised, spray the area

around the weld seams with cold galvanising spray

(not included in the scope of delivery) and allow to

dry for at least 30 minutes.

Touch up all damaged areas in the paint with the sup-

plied touch-up paint.

, page A12. Seal the slots between the load-

ing bridge frame and the building before pouring in

the concrete grout. We recommend that you cover

the loading bridge platform with a protection film be-

fore pouring in the concrete grout.

Summary of Contents for NovoDock L530

Page 139: ...A3 c 4 x...

Page 141: ...A5 c 4 x 181 250 mm DZ2 100 180 mm DZ1...

Page 150: ......

Page 151: ......

Page 152: ...docking Solution und Service GmbH Springrad 4 30419 Hannover Germany DS0805301 05 2022...