EN - 35

These assembly, operation and maintenance instructions must be kept for the entire period of use!

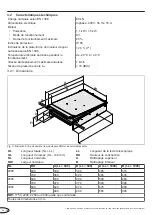

Pour in the concrete grout. Make sure to use con-

crete of appropriate quality, at least C20/25. If you

pour in the concrete grout from a great height, make

sure that the lateral pressure does not become too

high during the pouring and compaction process.

Otherwise, the side walls may deform.

Close the holes in the loading bridge platform with the

plastic plugs.

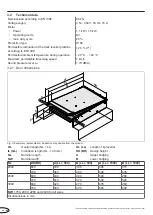

4.7.3 Installation condition BZ

, page A13. Weld the loading bridge to the

pre-frame.

If the dock leveller is galvanised, spray the area

around the weld seams with cold galvanising spray

(not included in the scope of delivery) and allow to

dry for at least 30 minutes.

Touch up all damaged areas in the paint with the sup-

plied touch-up paint.

Close the holes in the loading bridge platform with the

plastic plugs.

4.7.4 Installation condition EZ

, page A13. Weld the loading bridge to the re-

inforcement.

Seal the slots between the loading bridge frame and

the building before pouring in the concrete grout. We

recommend that you cover the loading bridge plat-

form with a protection film before pouring in the con-

crete grout.

Pour in the concrete grout. Make sure to use con-

crete of appropriate quality, at least C20/25. If you

pour in the concrete grout from a great height, make

sure that the lateral pressure does not become too

high during the pouring and compaction process.

Otherwise, the side walls may deform.

If the dock leveller is galvanised, spray the area

around the weld seams with cold galvanising spray

(not included in the scope of delivery) and allow to

dry for at least 30 minutes.

Touch up all damaged areas in the paint with the sup-

plied touch-up paint.

Close the holes in the loading bridge platform with the

plastic plugs.

5

Operation

5.1

Safety instructions for operation

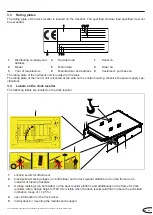

The dock leveller is designed to mitigate to the

greatest possible extent the risk of anyone operating

or standing near the door being crushed, cut, clipped

or otherwise injured. To ensure a safe operation of

the dock leveller, the following points must yet be ob-

served:

•

If you notice damages endangering the

operational safety of the dock leveller, the dock

leveller must be inspected by an expert or a

qualified person and may not be used until the

repair work has been completed.

•

Only instructed persons are allowed to operate

the dock leveller. All operators must be familiar

with the applicable safety regulations.

•

Comply with the accident prevention regulations

and general safety regulations relevant to the

field of application.

•

The operator of the dock leveller must ensure

sufficient lighting at the workplace.

•

Regularly check the loading ramp for obvious

defects and have defects rectified immediately.

•

Operating the dock leveller is only permissible at

temperatures between -20 °C and +40 °C.

•

Do not load the dock leveller with cargo

exceeding the specified nominal load.

•

Driving on the dock leveller is only allowed if the

permissible slope of 12.5 % (7°) is observed.

Orange markings on the loading bridge platform

and additionally on the frame for loading bridges

with a design height of 700 mm indicate that the

permissible inclination range is no longer met.

Also observe the permissible incline for the

operation of the forklift truck used.

•

The dock leveller platform may only be placed on

the truck loading area, not on a vehicle lifting

platform.

•

The permissible track width of the forklift truck

used must be 700 mm less than the nominal

width of the dock leveller (e.g. nominal width =

2000 mm → industrial truck width maximum

1300 mm).

•

Only move the vehicle to be loaded or unloaded

when the dock leveller is in its resting position.

•

The lip leveller width must be in the range of

80 mm to 130 mm. The entire width of the hinged

lip has to be placed on the truck.

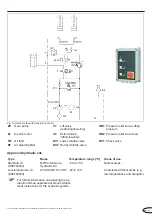

5.2

Operating the control unit

For operation, please read the assembly and operat-

ing instructions for the dock leveller control.

Summary of Contents for NovoDock L530

Page 139: ...A3 c 4 x...

Page 141: ...A5 c 4 x 181 250 mm DZ2 100 180 mm DZ1...

Page 150: ......

Page 151: ......

Page 152: ...docking Solution und Service GmbH Springrad 4 30419 Hannover Germany DS0805301 05 2022...