36 - EN

These assembly, operation and maintenance instructions must be kept for the entire period of use!

5.3

Dock leveller operation

WARNING

Crush hazard by moving dock

leveller!

Limb crush hazard by moving dock lev-

eller.

•

The dock leveller must be visible

from the place of operation.

•

During lifting and lowering the dock

leveller, it is not permitted to per-

sons to be in the travel path of the

dock leveller.

CAUTION

Tripping or falling hazard when the

dock leveller platform is raised!

When the dock leveller platform is

raised and not in use, there is a tripping

or falling hazard.

•

Put the dock leveller into rest posi-

tion immediately after use.

5.3.1 Positioning the truck

•

Make sure that there is no person or obstacle

between the dock leveller and the truck

approaching in reverse.

•

Position the truck with the door open and the tail

lift lowered.

•

Lock the truck in place using the brake and wheel

chock or safety wheel chock (optional).

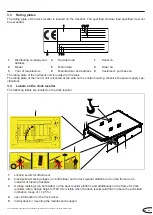

5.3.2 Placing the dock leveller on the truck

loading area

CAUTION

Falling hazard when loading!

If the contact surface of the lip leveller

on the truck loading area is too small,

the loading bridge platform can slip off.

•

The lip leveller width must be in the

range of 80 mm to 130 mm. The en-

tire width of the hinged lip has to be

placed firmly on the truck.

CAUTION

Tripping or falling hazard when

loading!

With the control switched off, triggered

emergency stop switch or active restart

lock, the floating position of the dock

leveller is not active and the vertical

movements of the truck are not bal-

anced out.

•

It is not permitted to drive on the

dock leveller until restart.

•

Place the lip leveller of the loading bridge on the

truck loading area.

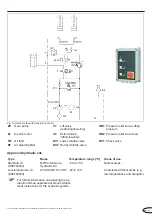

Also observe the assembly and operating in-

structions for the loading bridge control,

•

The loading bridge can now be driven over.

NOTICE

Deformations of the dock leveller due

to excessive loading

The lifting cylinders are equipped with

mechanical emergency stop valves.

These prevent the dock leveller platform

from sinking dangerously when the

dock leveller is in floating position. This

applies if there is still a load of at

least 25 % of the nominal load on the

dock leveller and if the truck should be

driven away prematurely. The heavy

loads caused by the response of the

mechanical emergency stop valves can

lead to permanent deformation of the

stressed components. These deforma-

tions do not constitute grounds for com-

plaint.

•

After response of the mechanical

emergency stop valves, have the

dock leveller inspected by an ex-

pert/ a qualified person.

•

Do not use the dock leveller for lift-

ing and lowering loads.

•

Put the dock leveller into rest position

immediately after use.

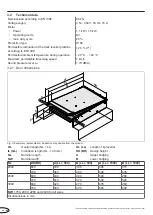

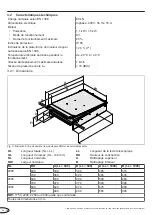

Summary of Contents for NovoDock L530

Page 139: ...A3 c 4 x...

Page 141: ...A5 c 4 x 181 250 mm DZ2 100 180 mm DZ1...

Page 150: ......

Page 151: ......

Page 152: ...docking Solution und Service GmbH Springrad 4 30419 Hannover Germany DS0805301 05 2022...