40 - EN

These assembly, operation and maintenance instructions must be kept for the entire period of use!

Equipment

Activity

Interval

Personnel

also see

chapter

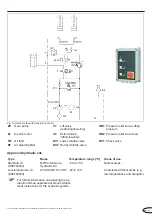

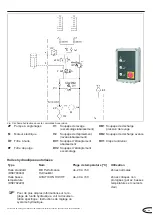

Control unit

visual inspection,

functional check

annually

expert/qualified person

8.6

state

visual inspection

daily

operator, skilled electrician

function

functional check

daily

operator, skilled electrician

function of main

switch

functional check

daily

operator, skilled electrician

emergency off

function

functional check

daily

operator, skilled electrician

secure against switch-

on

functional check

monthly

skilled electrician

electrical cables/

connections

visual inspection

monthly

skilled electrician

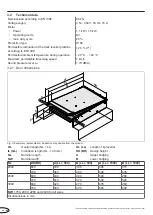

Hydraulic unit

visual inspection,

functional check

annually

expert/qualified person

8.7

function

functional check

daily, annually

operator, hydraulics specialist

safety devices

functional check

annually

hydraulics specialist

oil level

visual inspection

weekly, annually operator, hydraulics specialist

•

condition/

cleanliness

visual inspection

monthly

hydraulics specialist

•

replace

replacement

every two years

hydraulics specialist

oil filter

replacement

if soiled

hydraulics specialist

leaks

visual inspection

monthly, annually operator, hydraulics specialist

soiling

visual inspection

weekly

operator, hydraulics specialist

damages

visual inspection

monthly, annually hydraulics specialist

connection overview

visual inspection

annually

hydraulics specialist

noises

visual inspection

monthly, annually operator, hydraulics specialist

Hydraulic hoses

visual inspection

annually

expert/qualified person

8.8

damages

visual inspection

weekly, annually operator, hydraulics specialist

leaks

visual inspection

daily, annually

operator, hydraulics specialist

connection overview

visual inspection

annually

hydraulics specialist

replace

replacement

every six years

hydraulics specialist

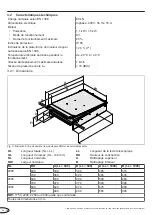

Hydraulic cylinders

visual inspection

annually

expert/qualified person

8.9

function

functional check

daily, annually

operator, hydraulics specialist

damages

visual inspection

annually

hydraulics specialist

leaks

visual inspection

daily, annually

operator, hydraulics specialist

fastenings

visual inspection

annually

hydraulics specialist

soiling

visual inspection

daily, annually

operator, hydraulics specialist

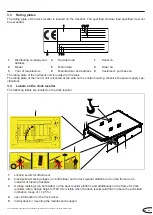

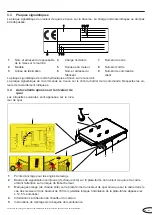

8.1

Safety information for maintenance

Before any maintenance, switch off the main switch

of the control unit and secure it against being

switched on again.

Mount the maintenance support (see chapter 4.6.3 -

Inserting the maintenance support).

A sign with the inscription "Maintenance work" must

be attached during each maintenance task.

If protective covers have been removed, replace

them after maintenance.

Check all screw connections for tightness after main-

tenance and tighten them if necessary.

8.2

General condition

•

Carry out a test run and make sure to test all

operating functions:

– lifting

– Extension of the lip leveller

– Lowering

– floating position

– moving back to the resting position

– emergency off function via main switch

Summary of Contents for NovoDock L530

Page 139: ...A3 c 4 x...

Page 141: ...A5 c 4 x 181 250 mm DZ2 100 180 mm DZ1...

Page 150: ......

Page 151: ......

Page 152: ...docking Solution und Service GmbH Springrad 4 30419 Hannover Germany DS0805301 05 2022...