EN - 41

These assembly, operation and maintenance instructions must be kept for the entire period of use!

•

Check these options, if available:

– automatic return to the resting position

– locking of door/dock leveller (sensor) or safety

wheel chock

– warning signal system (optical/acoustic)

•

Carry out a visual inspection on:

– mechanical damages, rust formation and the

condition of the welded construction

– dirt and oil spills in the area underneath the

dock leveller. Remove any if present.

•

Make sure that no debris, stones etc. obstruct the

function of the hinges.

•

Provide sufficient slip resistance by keeping the

dock leveller platform clean and dry.

•

Do not use any aggressive cleaning agents or

thawing salts! Risk of corrosion:

•

Do not aim a high-pressure water jet at the

control system, the hydraulic system or any

electrical connections!

If you notice damages the dock leveller must be in-

spected by an expert/ a qualified person and must not

be used until the repair work has been completed.

8.3

Signs/labels

Check the signs/labels for completeness, legibility

and condition according to chapter 3.3 and 3.4. La-

bels/rating plate must be replaced as required.

8.4

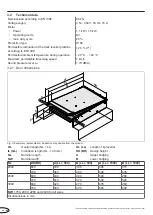

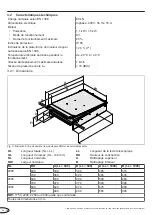

Design

Carry out a visual inspection of the entire steel con-

struction with regard to the following:

•

mechanical damages to the weld seams

•

completeness and tightness of the safety

elements and screw connections

•

deformations and corrosion

•

condition of the connection to the installation

point

Carry out the following checks on condition and func-

tion:

•

slip resistance condition of the drivable surfaces

•

condition of the anti-slip coating/sound-absorbing

coating (optional) of the dock leveller platform

•

protective plate

•

maintenance support

•

screw connection and safety cotter pins of the

hydraulic cylinders

•

safety cotter pins at the cross rod

•

all moving parts for ease of movement

If necessary, have the design inspected by an expert/

a qualified person.

8.5

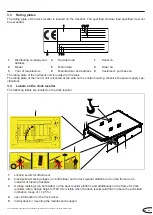

Hinges/ bearings

Lubricate the bearings on the loading bridge platform

through the tapered holes,the bearings of the lifting

cylinders as well as the sliding surfaces on both sides

of the lip leveller with multi-purpose grease (see ar-

rows).

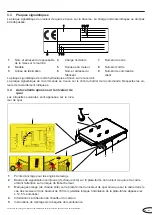

Fig. 7:

Lubrication points, illustration may deviate from the product

Summary of Contents for NovoDock L530

Page 139: ...A3 c 4 x...

Page 141: ...A5 c 4 x 181 250 mm DZ2 100 180 mm DZ1...

Page 150: ......

Page 151: ......

Page 152: ...docking Solution und Service GmbH Springrad 4 30419 Hannover Germany DS0805301 05 2022...