42 - EN

These assembly, operation and maintenance instructions must be kept for the entire period of use!

8.6

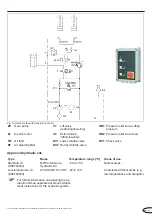

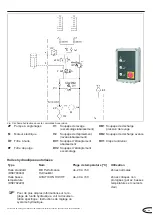

Control unit

To check the functions and to operate the

control unit, please observe the assembly

and operating instructions for the dock level-

ler control.

Emergency off function

After the interruption of the power supply, all move-

ments of the dock leveller must be blocked. It must

be possible to secure the main switch against inad-

vertent switch-on, e.g. by means of a lock that is dir-

ectly positioned at the main switch. The restart lock is

active afterwards. If the main switch is now actuated

again, the "Lift" button must first be pressed so that

the dock leveller is ready for operation again.

Carry out a visual inspection of the condition and

fastening of the electrical cables and plugs.

8.7

Hydraulic unit

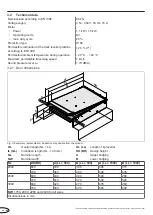

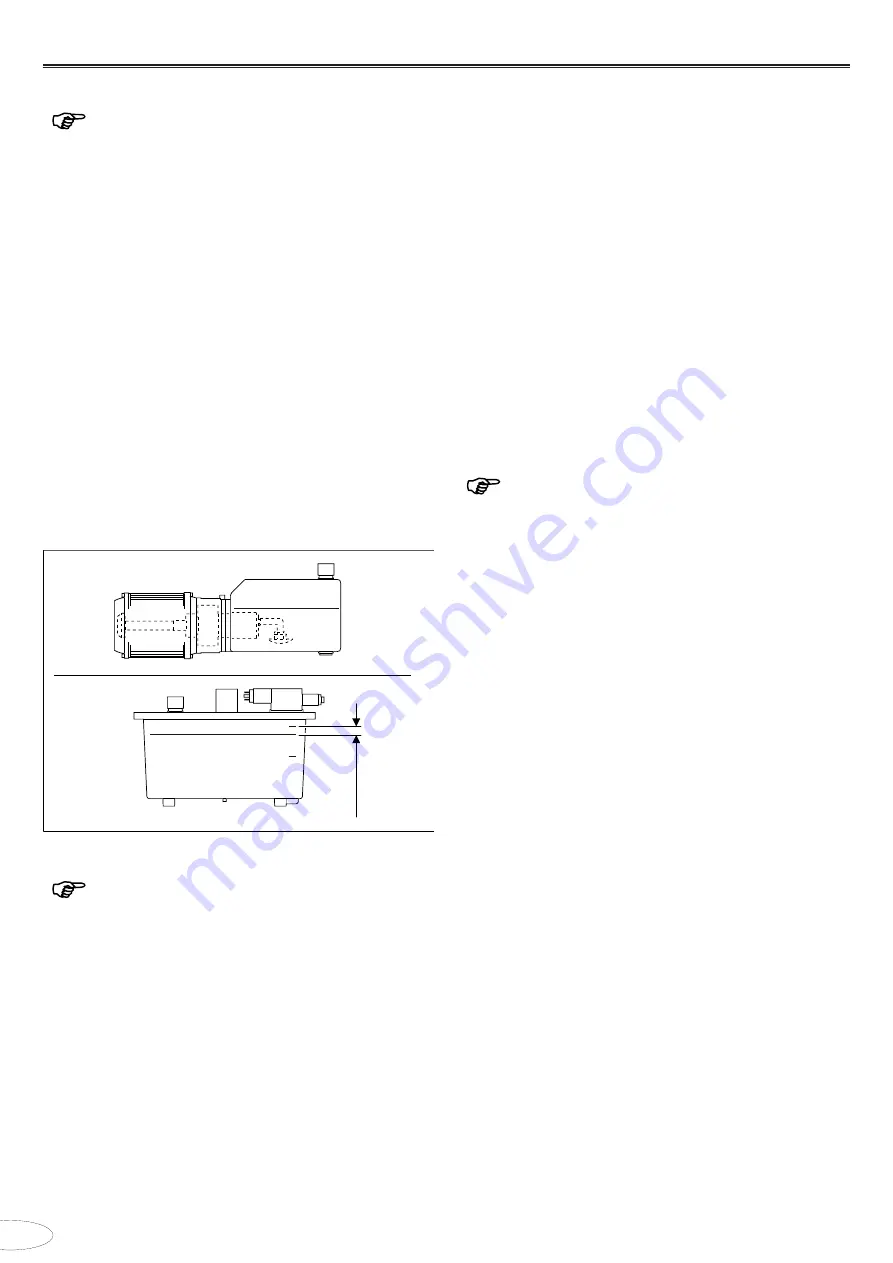

Checking the oil level

If the oil level of the hydraulic unit is too low, this will

lead to an increased oil temperature and faster oil

aging. The result are damages to the pump in the hy-

draulic unit.

MAX

MIN

optimal

MIN

m

a

x

. –

2

c

m

Fig. 8:

Oil level

Please refer to the separate document for

specifications on the optimum oil level: Ad-

justment instructions for the hydraulic system.

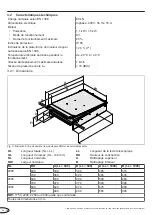

Changing the hydraulic oil

The quality of the hydraulic oil has a decisive effect

on the service life of the hydraulic unit. The mainten-

ance intervals depend on the intensity of use of the

dock leveller and should be performed more often

with an increased intensity of use. For this reason,

the oil quality should be checked at appropriate inter-

vals and, if necessary, the oil should be changed be-

fore the end of the interval as specified in the table.

The quality of the hydraulic oil can be assessed by

visual inspection.

If the following conditions occur, the oil is worn and

subject to premature oil aging and must be replaced:

•

Dark colouration, milky turbidity or bubble

formation

•

Burning odour

•

Contamination by foreign matter or suspended

particles

Use only hydraulic oils approved by the manufacturer

(see chapter 3.5 - Hydraulic system)!

For further information on changing the hy-

draulic oil see separate document: Adjust-

ment instructions for the hydraulic system.

8.8

Hydraulic hoses

All hydraulic hoses are subject to a recommended

service life of six years and should be replaced upon

expiry. Depending on the intensity of use of the dock

leveller, damages, leakages, signs of wear or corro-

sion on the hydraulic hoses, the recommended period

of use may also be considerably reduced.

The date of manufacture of the hydraulic hose can be

found on the hose fitting.

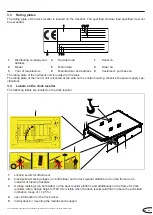

Replacing the hydraulic hoses

•

Move the dock leveller to its uppermost position.

•

Switch off the main switch and secure it against

switch-on.

•

Insert the maintenance support first at the top

and then at the bottom into the receptacle on the

dock leveller.

•

Switch on the main switch. Lower the dock

leveller.

•

Switch off the main switch and secure it against

switch-on. The hydraulic unit is blocked and the

hydraulic hoses are depressurised.

•

Make sure that the hydraulic system is

depressurised.

•

Dismantle the defective hydraulic hose and place

it in a suitable container to avoid oil

contamination.

•

Mount the new hydraulic hose and bleed the

system.

•

Check the oil level of the hydraulic unit and the

function of the dock leveller.

Summary of Contents for NovoDock L530

Page 139: ...A3 c 4 x...

Page 141: ...A5 c 4 x 181 250 mm DZ2 100 180 mm DZ1...

Page 150: ......

Page 151: ......

Page 152: ...docking Solution und Service GmbH Springrad 4 30419 Hannover Germany DS0805301 05 2022...