N1020 Temperature Controller

NOVUS AUTOMATION

6/8

DETERMINATION OF PID PARAMETERS

The determination (or tuning) of the PID control parameters in the

controller can be carried out in an automatic way and auto-adaptative

mode. The automatic tuning is always initiated under request of the

operator, while the auto-adaptive tuning is initiated by the controller

itself whenever the control performance becomes poor.

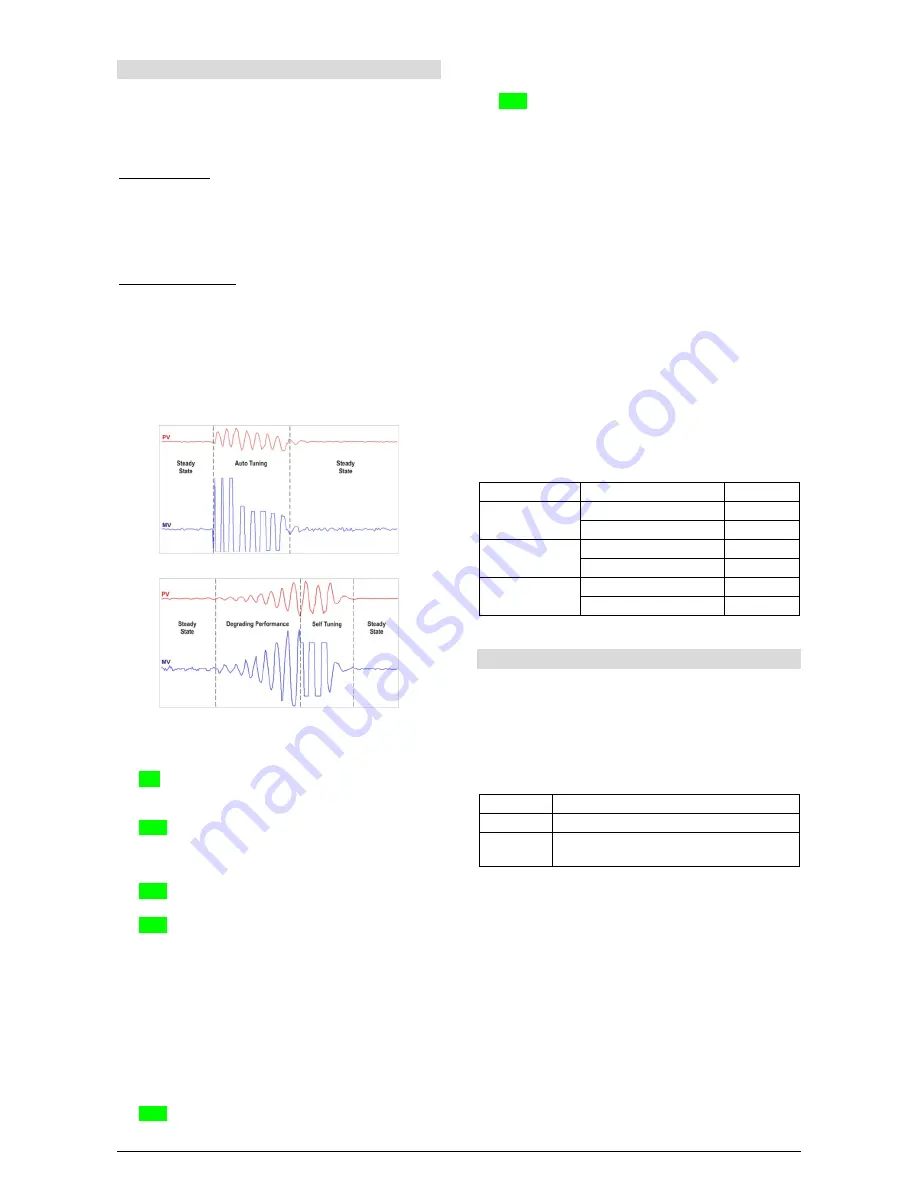

Automatic Tuning: In the beginning of the automatic tuning the

controller has the same behavior of an ON/OFF controller, applying

minimum and maximum performance to the process. Along the

tuning process the controller's performance is refined until its

conclusion, already under optimized PID control. It begins

immediately after the selection of the options FAST, FULL, RSLF or

TGHT, defined by the operator in the parameter ATUN.

Auto-adaptative Tuning: Is initiated by the controller whenever the

control performance is worse than the one found after the previous

tuning. In order to activate the performance supervision and auto-

adaptative tuning, the parameter ATUN must be adjusted for SELF,

RSLF or TGHT. The controller's behavior during the auto-adaptative

tuning will depend on the worsening of the present performance. If

the maladjustment is small, the tuning is practically imperceptible for

the user. If the maladjustment is big, the auto-adaptive tuning is

similar to the method of automatic tuning, applying minimum and

maximum performance to the process in ON/OFF control.

Fig. 04 – Example of auto tuning

Fig. 05 – Example of auto-adaptative tuning

The operator main select through the ATUN parameter, the desired

tuning type among the following options:

•

OFF

: The controller does not carry through automatic tuning or

auto-adaptative tuning. The PID parameters will not be

automatically determined nor optimized by the controller.

•

FAST

: The controller will the process automatic tuning one

single time, returning to the OFF mode after finishing. The tuning

in this mode is completed in less time, but not as precise as in

the FULL mode.

•

FULL

: The same as the FAST mode, but the tuning is more

precise and slower, resulting in better performance of the P.I.D.

•

SELF

: The performance of the process is monitored and the

auto-adaptative tuning is automatically initiated by the

controller whenever the performance poorer.

After a tuning level, the controller starts collecting data from the

process for determining the performance benchmark that will

allow evaluate the need for future tunings. This phase is

proportional to the process response time and is signaled by the

flashing TUNE indication on the display. It is recommended not

to turn the controller off neither change the SP during this

learning period.

It is recommended not to turn the controller off neither change the

SP during this learning period.

•

rSLF

: Accomplishes the automatic tuning and returns into the

SELF mode. Typically used to force an immediate automatic

tuning of a controller that was operating in the SELF mode,

returning to this mode at the end.

•

TGHT

: Similar to the SELF mode, but in addition auto-adaptative

tuning, it also executes the automatic tuning whenever the

controller is set in RUN=YES or when the controller is turned on.

Whenever the parameter ATUN is altered by the operator into a

value different from OFF, an automatic tuning is immediately

initiated by the controller (if the controller is not in RUN=YES, the

tuning will begin when it passes into this condition). The

accomplishment of this automatic tuning is essential for the correct

operation of the auto-adaptative tuning.

The methods of automatic tuning and auto-adaptative tuning are

appropriate for most of the industrial processes. However, there may

be processes or even specific situations where the methods are not

capable to determine the controller's parameters in a satisfactory

way, resulting in undesired oscillations or even taking the process to

extreme conditions. The oscillations themselves imposed by the

tuning methods may be intolerable for certain processes.

These possible undesirable effects must be considered before

beginning the controller's use, and preventive measures must be

adopted in order to assure the integrity of the process and users.

The AT signaling device will stay on during the tuning process.

In the case of PWM or pulse output, the quality of tuning will also

depend on the level time adjusted previously by the user.

If the tuning does not result in a satisfactory control, refer to Table 05

for guidelines on how to correct the behavior of the process.

PARAMETER

VERIFIED PROBLEM

SOLUTION

Proportional Band

Slow answer

Decrease

Great oscillation

Increase

Rate of Integration

Slow answer

Increase

Great oscillation

Decrease

Derivative Time

Slow answer or instability

Decrease

Great oscillation

Increase

Table 05 - Guidance for manual adjustment of the PID parameters

MAINTENANCE

PROBLEMS WITH THE CONTROLLER

Connection errors and inadequate programming are the most

common errors found during the controller operation. A final revision

may avoid loss of time and damages.

The controller displays some messages to help the user identify

problems.

MESSAGE

DESCRIPTION OF THE PROBLEM

----

Open input. No sensor o signal.

Err1

Err6

Connection and/or configuration errors. Check the wiring

and the configuration.

Other error messages may indicate hardware problems requiring

maintenance service.