N1040 Controller

NOVUS AUTOMATION

5/7

The master password is made up by the last three digits of the serial

number of the controller added to the number 9000. As an example,

for the equipment with serial number 07154321, the master

password is 9 3 2 1.

Controller serial number is displayed by pressing

for 5 seconds.

DETERMINATION OF PID PARAMETERS

During the process of determining automatically the PID parameters,

the system is controlled in ON/OFF in the programmed Setpoint. The

auto-tuning process may take several minutes to be completed,

depending on the system. The steps for executing the PID auto-

tuning are:

•

Select the process Setpoint.

•

Enable auto-tuning at the parameter “

Atvn

”, selecting

FAST

or

FULL

.

The option

FAST

performs the tuning in the minimum possible time,

while the option

FULL

gives priority to accuracy over the speed.

The sign TUNE remains lit during the whole tuning phase. The user

must wait for the tuning to be completed before using the controller.

During auto tuning period the controller will impose oscillations to the

process. PV will oscillate around the programmed set point and

controller output will switch on and off many times.

If the tuning does not result in a satisfactory control, refer to Table 05

for guidelines on how to correct the behavior of the process.

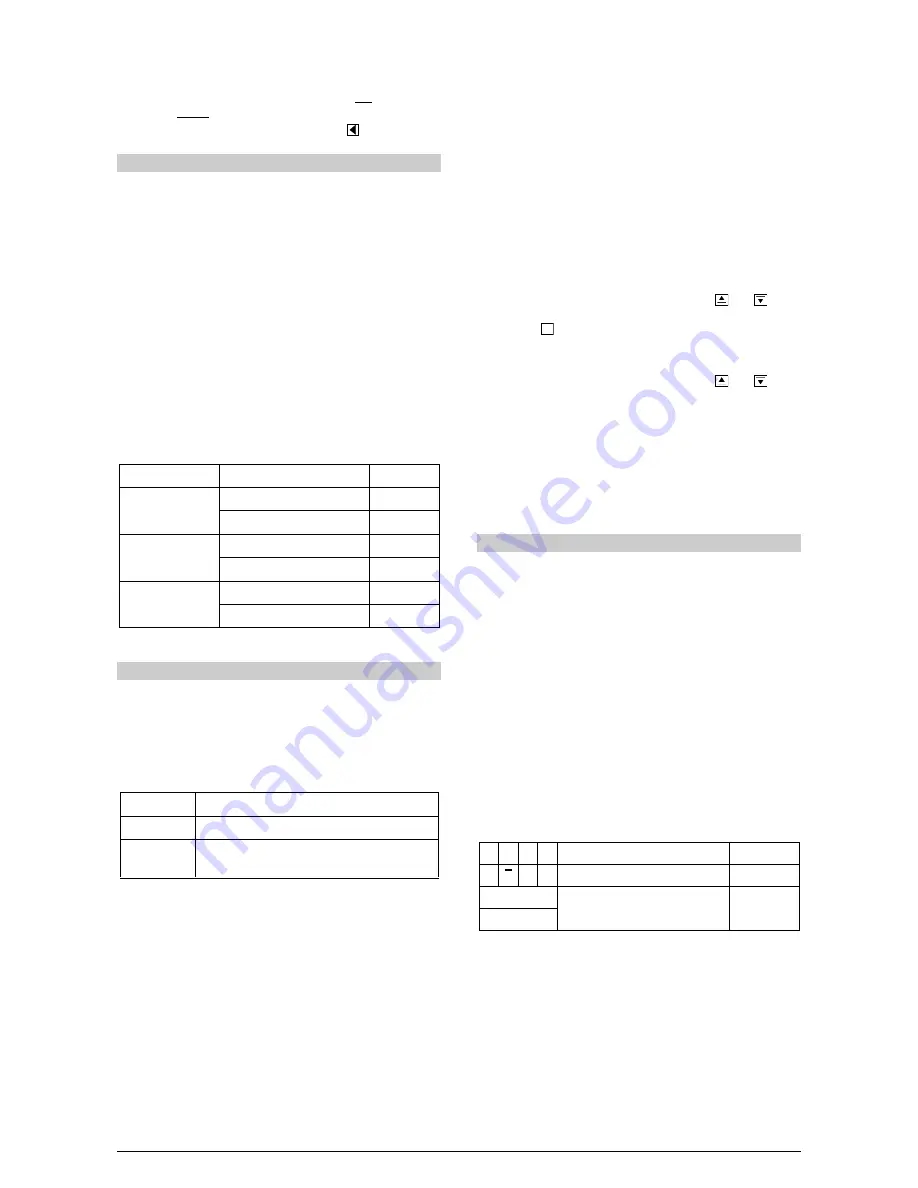

PARAMETER

VERIFIED PROBLEM

SOLUTION

Band Proportional

Slow answer

Decrease

Great oscillation

Increase

Rate Integration

Slow answer

Increase

Great oscillation

Decrease

Derivative Time

Slow answer or instability

Decrease

Great oscillation

Increase

Table 05 - Guidance for manual adjustment of the PID parameters

MAINTENANCE

PROBLEMS WITH THE CONTROLLER

Connection errors and inadequate programming are the most

common errors found during the controller operation. A final revision

may avoid loss of time and damages.

The controller displays some messages to help the user identify

problems.

MESSAGE

DESCRIPTION OF THE PROBLEM

----

Open input. No sensor or signal.

Err1

Err6

Connection and/or configuration problems.

Check the wiring and the configuration.

Other error messages may indicate hardware problems requiring

maintenance service.

CALIBRATION OF THE INPUT

All inputs are factory calibrated and recalibration should only be done

by qualified personnel. If you are not familiar with these procedures

do not attempt to calibrate this instrument.

The calibration steps are:

a) Configure the input type to be calibrated in the

type

parameter.

b) Configure the lower and upper limits of indication for the maximum

span of the selected input type.

c) Go to the Calibration Level.

d) Enter the access password.

e) Enable calibration by setting YES in

(alib

parameter.

f) Using an electrical signals simulator, apply a signal a little higher

than the low indication limit for the selected input.

g) Access the parameter “

inLC

”. With the keys and adjust

the display reading such as to match the applied signal. Then

press the key.

h) Apply a signal that corresponds to a value a little lower than the

upper limit of indication.

i) Access the parameter “

inLC

”. With the keys and adjust

the display reading such as to match the applied signal.

j) Return to the Operation Level.

k) Check the resulting accuracy. If not good enough, repeat the

procedure.

Note: When checking the controller calibration with a Pt100

simulator, pay attention to the simulator minimum excitation current

requirement, which may not be compatible with the 0.170 mA

excitation current provided by the controller.

SERIAL COMMUNICATION

The controller can be supplied with an asynchronous RS-485 digital

communication interface for master-slave connection to a host

computer (master).

The controller works as a slave only and all commands are started by

the computer which sends a request to the slave address. The

addressed unit sends back the requested reply.

Broadcast commands (addressed to all indicator units in a multidrop

network) are accepted but no reply is sent back in this case.

CHARACTERISTICS

•

Signals compatible with RS-485 standard. MODBUS (RTU)

Protocol. Two wire connection between 1 master and up to 31

(addressing up to 247 possible) instruments in bus topology.

•

Maximum connection distance: 1000 meters.

•

Programmable speed; 8 data bits; 1

stop

bit; selectable parity

(none);

The RS-485 signals are:

D1 D D + B Bi-directional data line.

Terminal 15

D0

D - A Bi-directional inverted data line.

Terminal 16

C

Optional connection that improves the

performance of the communication.

Terminal 17

GND

P

D: