Indicator N1500

NOVUS AUTOMATION

4/7

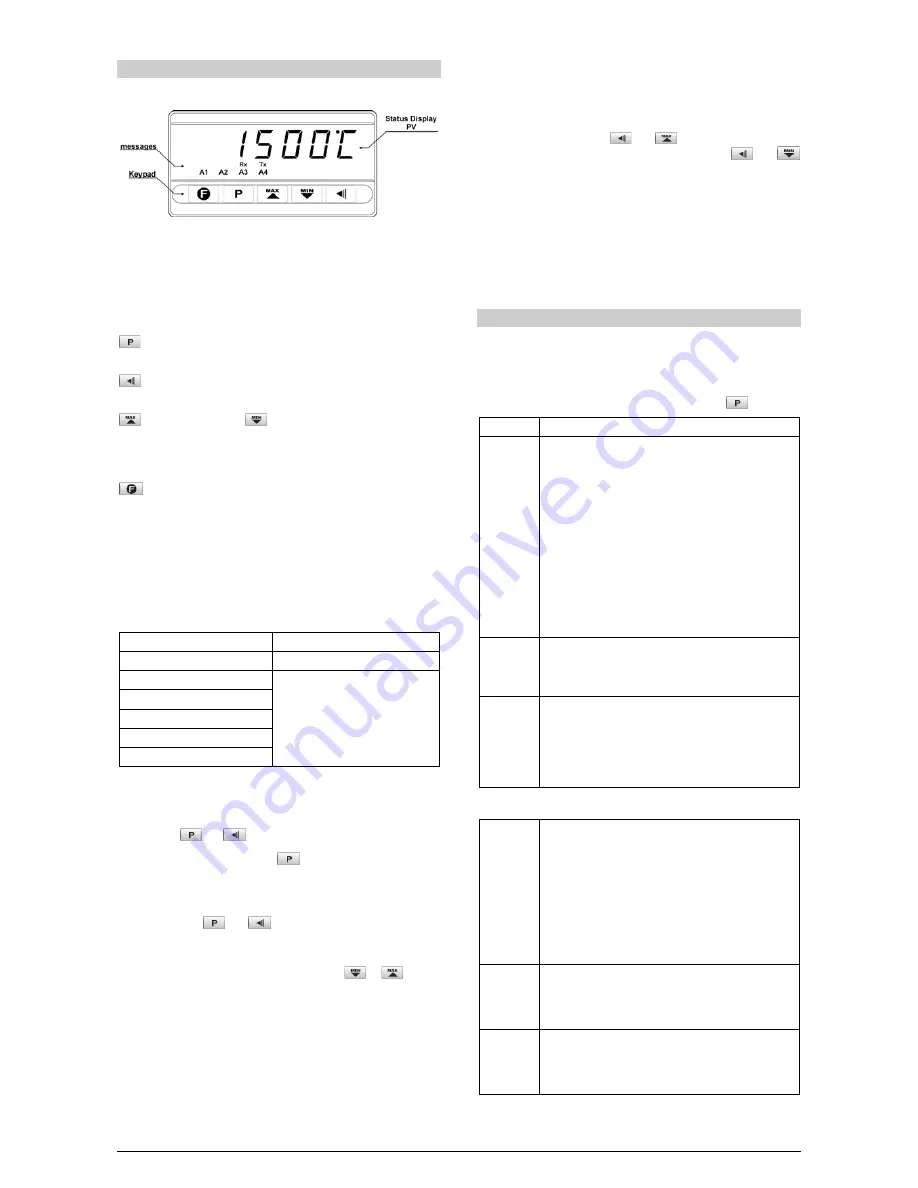

OPERATION

The front panel is shown below.

Fig. 10 - Front panel identification

Status Display: Shows the process variable (PV) and the

programming prompts.

Indicators A1, A2, A3 and A4: show active alarms.

Indicators Rx and Tx: indicate RS485 communication line is active.

PROGRAM key - This key is used to access different

displays with the programmable parameters of the device.

BACK key - This key is used to go back to the previous

parameter displayed in the menu level.

UP / MAX and

DOWN / MIN key – It is used to

increase and decrease parameters values. These keys are

also used to display maximum and minimum values stored

in memory.

FUNCTION key - This special function key is used for pre-

programmed functions as explained in the special function key

section of this manual.

The indicator requires that the internal parameters be properly

configured such as to fit the application need. These parameters are

the input type (T/C, Pt100, 4-20 mA, etc), alarms triggering points,

alarm functions, etc.

These parameters are divided in five levels (or groups) of parameters

which we will refer to as LEVELS.

LEVEL

ACCESS

1- Work

Free access

2- Alarms

Reserved access

3- Functions

4- Configuration

5- Customized Linearization

6- Calibration

Table 4 - Parameters Levels

The work level has free access. All other levels require a certain

combination of key strokes to be accessed. The combination is:

and

keys pressed simultaneously

Once within a level, just press

to move to the subsequent

parameters of this level. At the end of each level the display will go

back to the work level.

NOTE: In order to access the calibration level, however, it’s required

to press the keys

and

simultaneously for 10 seconds. The

first parameter in this level is presented (

In.LoC

) indicating that the

calibration level is enabled.

After reaching the intended prompt just press the

or

keys to

change this parameter accordingly. All changes are recorded in non-

volatile memory as we move to next prompt. After 25 seconds with no

key pressed the indicator will return to the measuring level (work level).

CONFIGURATION PROTECTION

As safety measure, parameter changes can be prevented by a

combination of keys, valid for each level. The protected parameters

can be inspected but not modified.

To protect a level press the

and

keys simultaneously for 3

seconds while in the level. To unlock the level, press

and

for 3 seconds.

The display will briefly flash confirming that the level was

successfully locked or unlocked.

For further protection, the keypad unlock operation can be disabled

by changing the position of an internal strap inside the indicator:

When PROT is OFF, the user is allowed to lock and unlock the levels

using the keypad as explained above. If PROT is ON, the levels

lock/unlock operation is disabled.

PROGRAMMING THE INDICATOR

WORK LEVEL

This is the first level. At power up the indicator will display the Process

Variable (PV). The alarm triggering points are also displayed at this level

(alarm Setpoints). To advance in this level simply press

.

SCREEN

PROMPT PARAMETER DESCRIPTION

8.8.8.8.8.

PV Measurement. Shows the measured variable. For

Pt100 or thermocouples the display will show the absolute

temperature value.

For 4-20 mA, 0-50 mV, 0-5 V and 0-10 mV inputs the

display shows the values defined in the “

in.LoL

” and

“

in.kiL

” parameters.

With the hold function programmed the display shows the

frozen variable and alternates with the message “

koLd

”.

Likewise, with Peak Hold function programmed the high

limit is displayed with the “

P.koLd

” prompt alternately.

Should any fault situation occur the indicator will display an

error message which can be identified at item 10 of this

manual.

Al.ref

Differential Alarm Reference Value - This prompt is

shown only when there is an alarm programmed with

differential function. This value is used as a reference for

differential alarms triggering.

Sp.al1

Sp.al2

Sp.al3

Sp.al4

Alarms Set Points 1, 2, 3 and 4 - Defines the operation

point of each alarm programmed with “

Lo

” or “

ki

”

functions.

When an alarm is programmed with a differential function,

the alarm setpoint value represents the deviation value of

the alarm relative to the reference

Al.ref

.

ALARM LEVEL

fV.al1

fV.al2

fV.al3

fV.al4

Alarm Function - Defines functions for the alarms 1, 2, 3

and 4.

oFF

: Alarm off

iErr

: Broken or Shorted Sensor

Lo

: Low value

ki

: High value

DiF.Lo

: Differential low

DiF.Hi

: Differential high

DiF.ov

: Differential outside the range

DiF.in

: Differential within range

Ky.al1

Ky.al2

Ky.al3

ky.al4

Alarm Hysteresis

This is the difference from the measured value to the point

where the alarm is turned ON and OFF.

Bl.al1

Bl.al2

Bl.al3

bl.al4

Alarm Blocking

Should any alarm condition occur, the alarms can be

individually disabled when energizing the indicator.