-

52

-

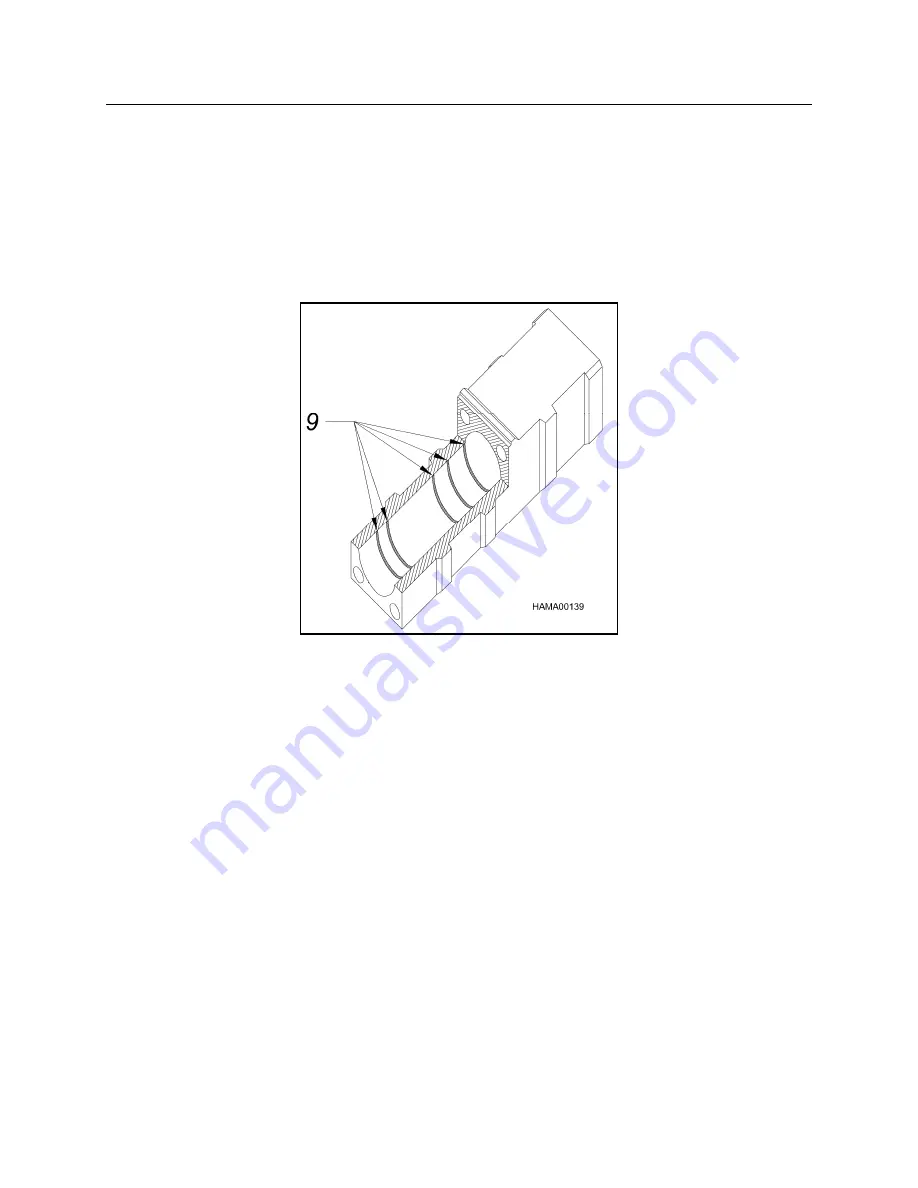

MAIN BODY BORE REPAIR

INSPECTION AND GENERAL POLISHING OF MAIN BODY

After disassembly and cleaning of the hammer components, it is important to

carefully inspect the hammer main body bore.

1. Using a light, look into the bore and identify all locations (

9

) of the o-rings that

seal the sleeve O.D. to the body. These areas can be recognized by the black

markings left in the bore from the o-rings resting in these areas.

2. If no damage is noted in the o-ring areas, use a ball hone to break the glaze in

the bore of the body.

DO NOT USE A FIXED HONE! USE ONLY 6 STROKES

OF A BALL HONE!

REMEMBER: ONCE THE SLEEVES ARE INSTALLED, THE O-RINGS BECOME

STATIONARY AND DO NOT MOVE OUT OF THE AREA THEY REST IN.

3. If a scratch runs across several o-ring areas:

a. Polish o-ring rest areas to blend with surrounding area.

b. If scratches are not removed by use of a ball hone, see

Repairing Body

Bore By Grinding and Polishing.

4. If score in o-ring area is too deep to polish and blend, the body may be welded in

these areas and hand ground / polished, see

Repairing Body Bore By Welding

and Polishing.