Page 13

CLEANING AND MAINTENANCE

Caution

Always be sure that the tool is switched off and unplugged before attempting to perform inspection

or maintenance.

Caution

The polisher air vents need to be kept clean. Regularly clean the grinder air vents or clean the vents

whenever they start to become obstructed.

Caution

To maintain product SAFETY and RELIABILITY, repairs to the polisher should be done by an Authorized

or Factory Service Center.

The following procedure will extend the longevity of your Seam Phantom®

1.

Blow out the electric polisher - Blow out polisher air vents after each use using a dry air supply

to remove any dust or moisture. This will extend the life of the electric motor.

2.

Cleaning Guide Rods and Bushings - After heavy use, the in and out adjustment of the Seam

Phantom® may become “stiff”. Performing the following steps should correct this. See Figure 6

below.

a.

Turn the adjustment knob counter clockwise until the adjustment screw disengages from the

square nut and the two halves of the Seam Phantom® can be separated. Do not lose the

square nut.

b.

Use a paper towel or other soft material and push through the bushing holes, sliding back

and forth until all grit is removed.

c.

Using a soft towel or material, wipe the stainless shaft guide rods clean.

d.

Clean screw threads on the adjustment screw with water and a brush.

e.

Reassemble the two halves of the Seam Phantom®

!

!

!

Summary of Contents for 0010-1

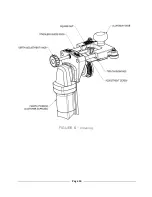

Page 14: ...Page 14 FIGURE 6 Cleaning...