Page 26 of 32

© Brüel & Kjær Vibro

● C104958.002 / V04

Technical alterations reserved!

EN

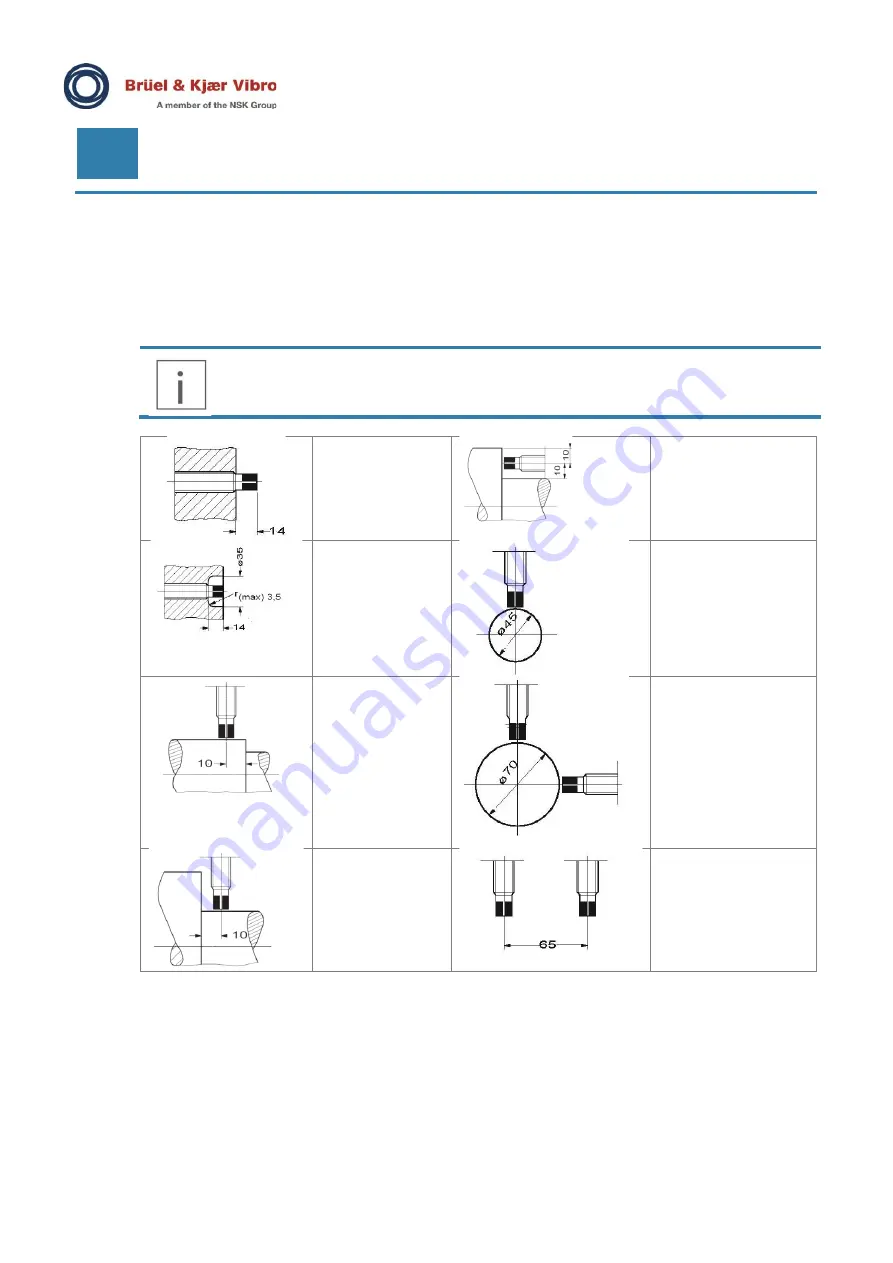

8.3.3

Required clearances and minimum distances for displacement sensors

Non-contacting eddy-current displacement sensors produce a high frequency electromagnetic field. If

electrically conductive material other than the object to be measured is located inside this field, the

measurement result will be distorted.

When assembling your non-contacting displacement sensors, strictly observe the clearances and

minimum distances illustrated in the following drawing.

NOTE!

If these clearances and minimum distances must be lowered for design purposes,

please contact Brüel & Kjær Vibro.

Sensor tip

extending

Distance to the shaft

shoulder sensor, parallel

to electrically conductive

material

Sensor tip flush

Required minimum

diameter of the shaft for

one sensor

Distance to a shaft

end > 100 % cover

Required minimum

diameter of the shaft for

two sensors

Distance to the

shaft shoulder

sensor, parallel to

electrically

conductive material

Parallel arranged

sensors