© Brüel & Kjær Vibro

● C104958.002 / V04 ●

Page 17 of 32

Technical alterations reserved!

Brüel & Kjær Vibro

│

Instructions Sensor ds821 4 mm

Installation

EN

UNRESTRICTED DOCUMENT

4.4

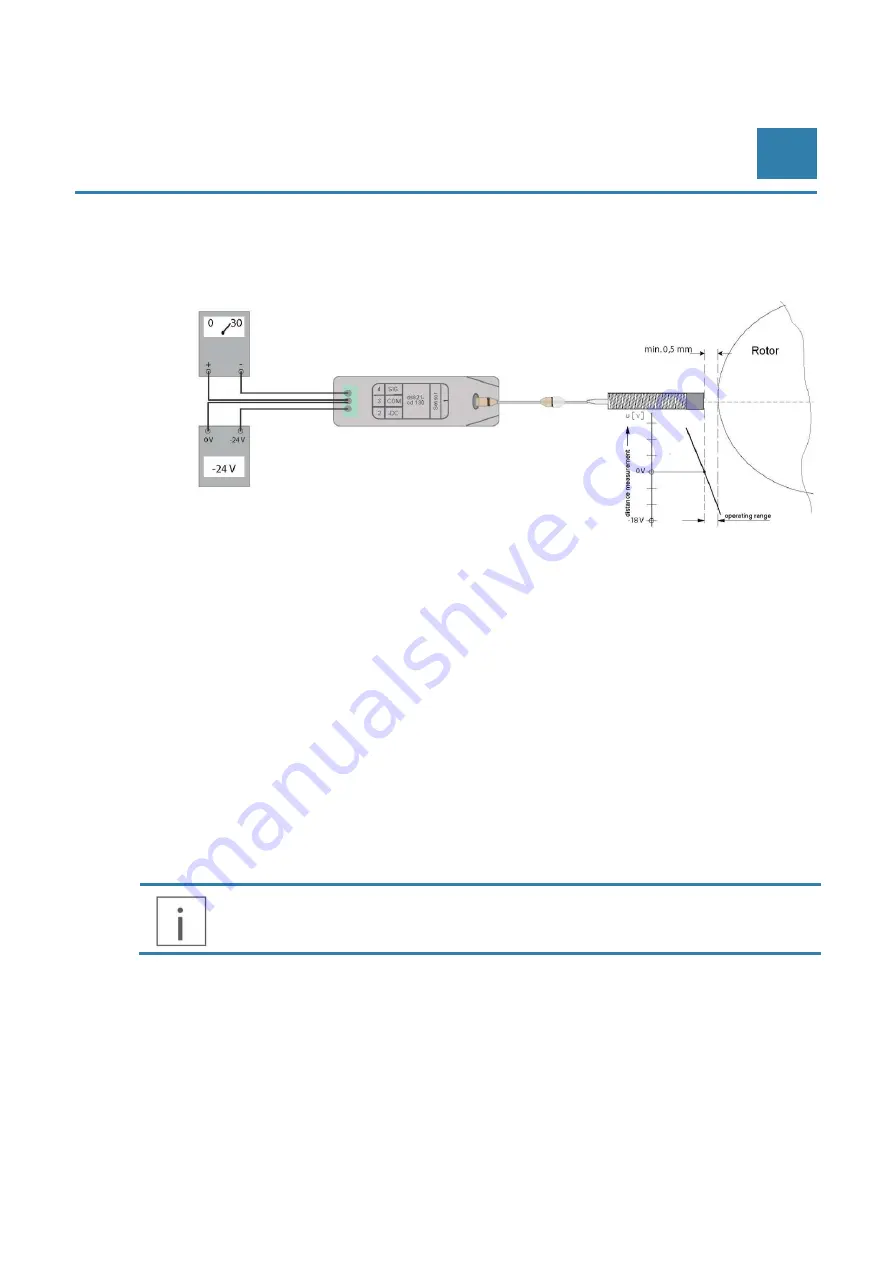

Setting up the measuring chain and the displacement sensor

The displacement sensor should be adjusted when the rotor is stationary.

4.4.1

Measurement set-up

As a rule, a displacement measuring chain is adjusted with the help of a voltmeter and the "operating

voltage". The measuring system is adjusted through the position of the sensor type to the object to be

measured. The displacement sensor is inserted and fixed in place by positioning it in the linear

measuring range (see drawing). To avoid damaging the sensor tip, the prescribed minimum

separation to the shaft (maximum displacement) must be maintained.

The minimum distance to the target must be selected so that even in the event of maximum deflection

of the shaft the distance (axial or relative to the shaft) does not fall below 0.5 mm.

In case of an axial measurement, the axial bearing clearance design and the current position of the

shaft must be considered in order to prevent damage to the sensor tip.

•

The displacement sensor system is fully assembled and connected to a power supply and a

monitoring system.

•

The physical separation should lie between 0.5 mm and max. 4.5 mm.

➔

Switch on the voltage for the driver.

You will obtain an output signal proportional to the measurement distance in the range -2

V…-18 V.

Adjust the separation of the sensor until the required output signal is present.

NOTE!

Use the characteristic curve U [GAP] to determine your minimum distance.