APPENDIX

SERVICE BOOK

Although the sterilizer’s average life is about 8-12 years, it is compulsory to carry out periodic controls in order

to check the correct calibration and for possible wear of components. The control interval, as reported on the

Service Book, is 1 year or 1500 cycles for the ordinary maintenance, and 4 years or 10.000 cycles for the

special maintenance. The sterilizer is configured to signal on the display, as the first term comes to expire,

the message “ NEED SERVICE”. This feature is in compliance with the norm EN13060 and answers to spe-

cific safety requirements. The maintenance activities must be performed by authorized technicians ( provided

with card or certificate released by

NSK

) and reported on this Service Book.

Model .................................................................

Serial Number .............................

Installation Date ...................................................

Altitude .......................................

Installer ...........................................................................................................................

Reseller ............................................................................................................................

Sterilization Manager: ...................................................................................................... .

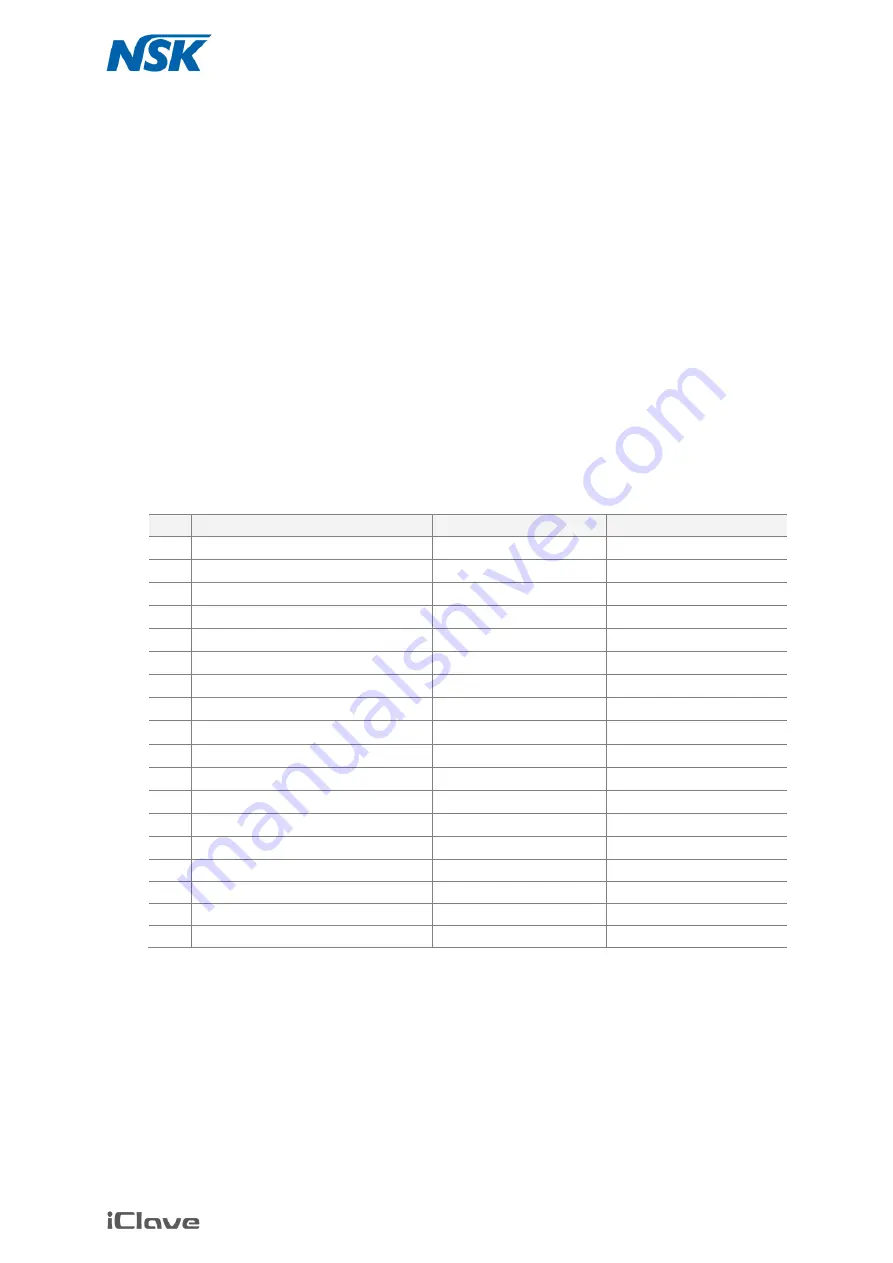

Standard periodic checks

Pos.

Check/Activity

Ordinary maintenance

Special maintenance *

1

Door adjustment

1 Year / 1.500 cycles

- Gasket replacement

1 Year / 1.500 cycles

- Disk-door clearance check

1 Year / 1.500 cycles

- Closing force check

1 Year / 1.500 cycles

- Lubrication

1 Year / 1.500 cycles

- Component wear check

1 Year / 1.500 cycles

- Closing pin replacement

4 Years / 10.000 cycles

- Screw hinge replacement

4 Years / 10.000 cycles

- Screw tightening

4 Years / 10.000 cycles

2

Calibration / Validation

1 Year

- Altitude setting check

1 Year / 1.500 cycles

3

Filter cleaning / replacement

1 Year / 1.500 cycles

- Bacterial filter replacement

6 Months / 500 cycles

4

Pump feature check

1 Year / 1.500 cycles

- Pump replacement

10.000 cycles

5

Tank cleaning

1 Year / 1.500 cycles

6

Condenser cleaning

1 Year / 1.500 cycles

7

Safety valve replacement

4 Years / 10.000 cycles

*) To be carried out in factory’s

service department

In case of direct ship or consign for shipping the sterilizer for service center or factory repairing, include a copy of

the filled Service Book pages.