— 13-2 —

13.2. Maintenance Check

13.2.1. Motor

l

Since a Megathrust Motor does not have any parts which will wear out, a daily maintenance

check should be enough.

l

The table below shows the maintenance check and intervals. The checking interval shown in the

table is reference only. It should be decided according to the actual use conditions.

!

Caution : Do not disassemble the Motor and resolver. If disassembling Motor is

necessary, contact your local NSK representative.

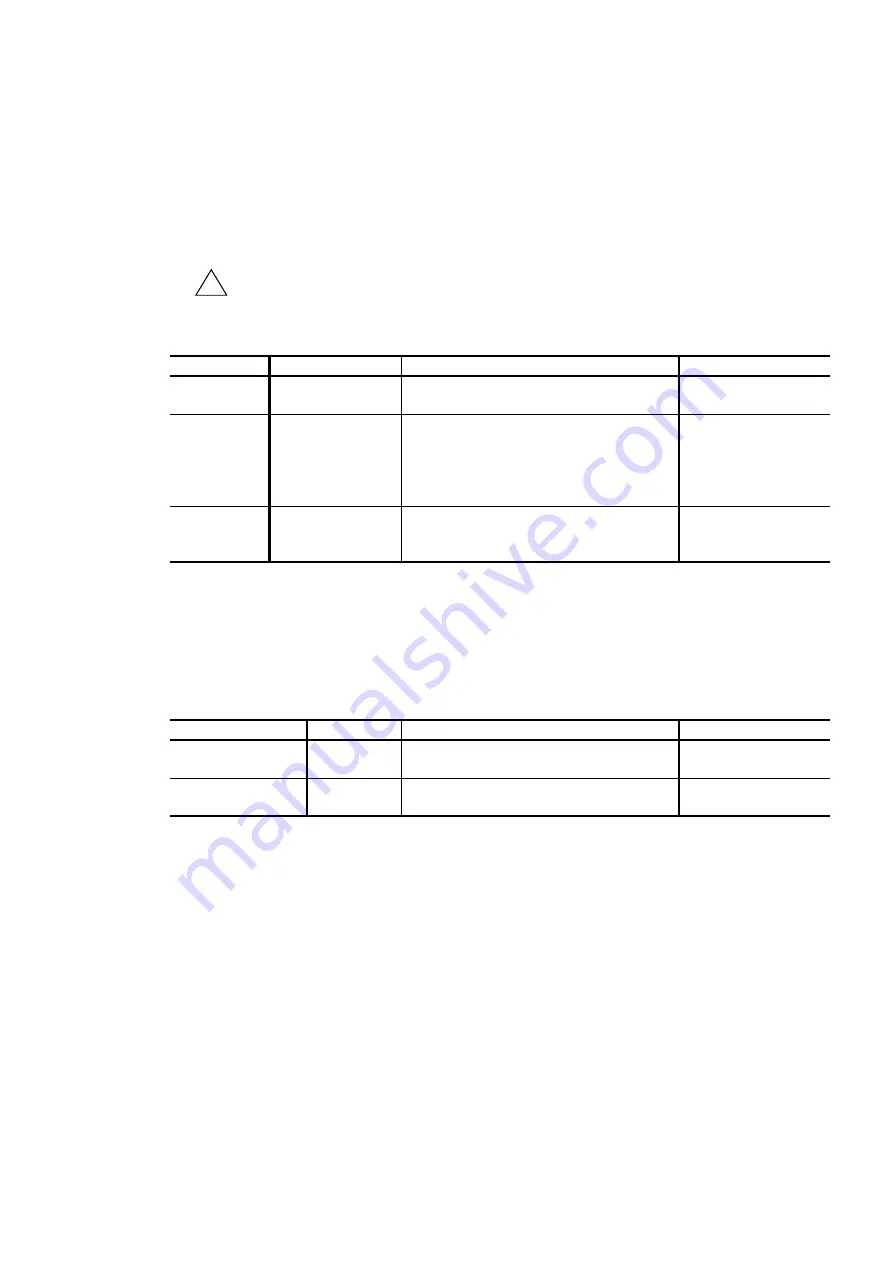

Table 13-1: Motor maintenance check

Item

Checking interval

How to check

Remarks

Appearance

According to

environment

·

Wipe off dust/slag.

·

Blow off slag.

–

Greasing

Every 6 months

·

Check dirt and contamination.

·

Supply grease via the grease nipples on

both ends of the slider every 6 months

approximate. In case of HZ type Motor,

grease directly onto the rail grooves.

·

Grease : AV2

Insulation

Once/year

·

Resistance test

(Motor coil and ground earth)

(Disconnect Driver Unit)

·

Resistance

³

10M

W

13.2.2. Driver Unit and Cable Set

l

As a Driver Unit does not have any contact point and highly reliable semiconductors are used,

the daily check is not necessary. Checks as shown in Table 13-2 are necessary at least once a

year.

Table 13-2

Item

Interval

Check point

Remarks

Retighten screws

Once/year

·

Terminal block screw.

·

Connector fixing screw.

–

Cleaning

Once/year

·

Remove dust or contaminants inside of

Driver Unit.

–

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com