3

CN1 signal and Pin number.

■

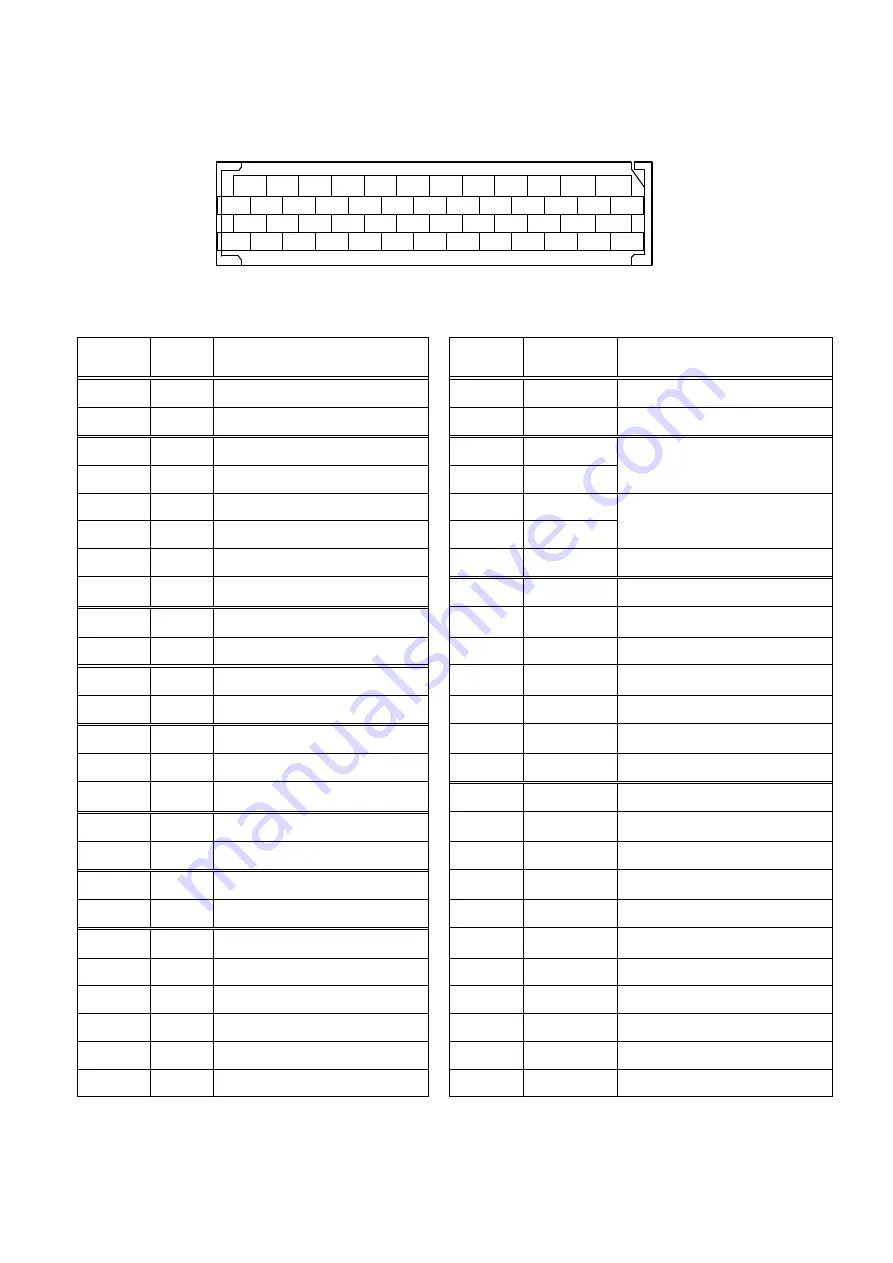

CN1

10150-3000PE (Soldering side view)

Signal name and its function. (shipping set)

Terminal

number

Signal

name

Description

Terminal

number

Signal

name

Description

1

-

Do not connect

30

MON1

Analog monitor output

2

-

Do not connect

31

SG

Common for pin 30

3

A0

A phase pulse output

13

CONT7

Position command pulse

disabled function/shutdown at

zero velocity function

4

A0

/A phase pulse output

14

CONT7

5

BO

B phase pulse output

15

CONT8

Alarm reset function

6

BO

/B phase pulse output

16

CONT8

7

ZO

Z phase pulse output

38

SG

Common for pins 13 to 16

8

ZO

/Z phase pulse output

32

CONT6

CW over travel function

9

PS

Resolver signal output

33

CONT5

CCW over travel function

10

PS

/Resolver signal output

34

CONT4

Deviation clear function

11

ZOP

Z phase pulse output

35

CONT3

Magnetic pole position estimation input

12

SG

Common for pins 3 to 11

36

CONT2

Emergency stop function

17

-

Do not connect

37

CONT1

Servo-ON function

18

-

Do not connect

50

CONT-COM

General input power supply

19

-

Do not connect

39

OUT1

In-Position window

20

-

Do not connect

40

OUT2

Magnetic pole position estimation ready

21

-

Do not connect

41

OUT3

Operation setup completion

22

T-COMP

Torque compensation input

42

OUT4

Magnetic pole position estimation end

23

SG

Common for pin 22

43

OUT5

Alarm code bit 5

26

F-PC

CW command pulse input

44

OUT6

Alarm code bit 6

27

F-PC

CW command pulse input

45

OUT7

Alarm code bit 7

28

R-PC

CCW command pulse input

46

OUT8

Alarm status

29

R-PC

CCW command pulse input

49

OUT-PWR

Power source for general output

47

SG

Common for pins 26 and 27

24

OUT-COM

General output Common

48

SG

Common for pins 28 and 29

25

OUT-COM

General output Common

24

22

20

18

16

14

12

10

8

6

4

2

25

23

21

19

17

15

13

11

9

7

5

3

1

49

47

45

43

41

39

37

35

33

31

29

27

50

48

46

44

42

40

38

36

34

32

30

28

26