5

5. Initial setting

Please change parameter setting value of Model EGA driver required according to the conditions to be used.

Use application software

“

MEGATORQUE MOTOR SETUP

”

to set the parameters.

◆

Single phase AC main power

Change

“

System parameter_ID01 : main circuit power input type

”

to

“

01 : AC Single-phase

”

, then connect

AC power line

to terminal R and T of connector CNA.

◆

CN1 I/O signal configuration

The pin-out arrangement and polarity of signals from CONT1 to CONT8 can be changed by setting of

parameter

“

Gr.9_Function enabling condition settings

”

, and pin-out arrangement of signals from OUT1 to OUT8

can be changed by

“

Gr.A_General output terminal output condition / Monitor output selection / Serial

communication settings

”

.

Input signals

“

Gr.9_ID00:CW Over Travel function(F-OT)

”

,

“

Gr.9_ID01:CCW CW Over Travel

function(R-OT)

”

, and

“

Gr.9_ID42:Emergency Stop Function(EMR)

”

are normal close polarity input as

shipping set.

To enable motor operation, wire these input signals properly, or change its polarity by parameter setting value.

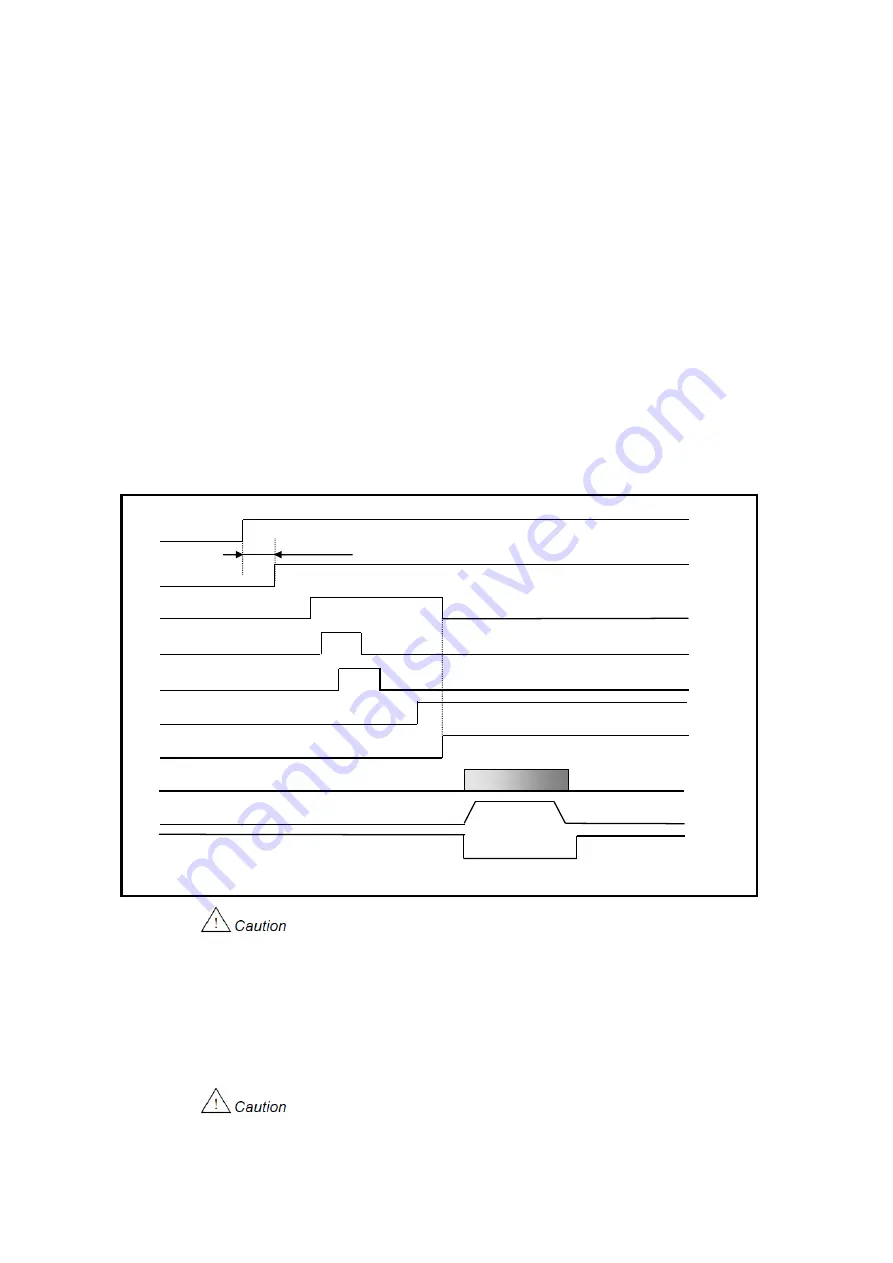

6. Operation sequence

0 msec (Min)

Control source

Main circuit power

Magnetic Pole Position Estimation

ready signal (output)

Magnetic Pole Position Estimation

input signal (input)

Magnetic Pole Position Estimation

end signal (output)

Servo On signal (input)

Motor speed

Operation set up completion signal (output)

Pulse command

In Position window (output)

:

The magnetic pole position estimation must be conducted everytime when

power is turned on.

Magnetic pole position estimation will cause the motor rotation reciprocally

maximum of +/-18 degree.

Do not apply external and/or unbalanced force to the motor to complete

magnetic pole position estimation process properly.

Start motor operation after completion of magnetic pole estimation process.

:

Install external Home sensor if homing operation is required.

Motor incorporates incremental sensor, no absolute sensor is incorporated.