20

If you are suspecting any faults, check the following once again prior to asking for repair work. If none of these cases is applicable or if the situation does not

improve despite your efforts or measures, the damage could be serious; call your dealer to fix the problem.

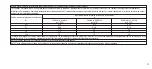

<Motor (without Hand Control) >

Symptoms

Causes/Points of checking

Countermeasures

No rotation after a bur and other instruments

has been attached.

The Twist Collet on the Attachment/Handpiece is

OPEN.

After inserting the Bur, fasten the Twist Collet.

(Turn it in the direction of ' ')

· The bearing has seized.

· Foreign substance inside the bearing.

· The bearing is worn out.

Contact your dealer.

Abnormal heating during rotation.

Continuous use over a long period.

Stop operating the Attachment/Handpiece and Motor

immediately. Wait until the Attachment/Handpiece and

Motor cool down before continuing to operate.

· The bearing has seized.

· Foreign substance inside the bearing.

· The bearing is worn out.

Contact your dealer.

6

Troubleshooting